Laboratory and Process Analyzers

Automatic Analysers → NewLab Range • OilLab Range • Thermofat • OnLine Range

RVP - Reid Vapour Pressure • Salts in Crude Oil

This test method covers procedures for the determination of vapour pressure of gasoline, volatile crude oil, and other volatile petroleum products.

Procedure A is applicable to gasoline and other petroleum products with a vapour pressure of less than 180 kPa (26 psi).

Procedure B may also be applicable to these other materials, but only gasoline was included in the interlaboratory test program to determine the precision of this test method.

Procedure C is for materials with a vapour pressure of greater than 180 kPa (26 psi).

Procedure D for aviation gasoline with a vapour pressure of approximately 50 kPa (7 psi).

Different regulations agree about the fact that Reid vapour pressure (RVP) is a key property in determining whether a substance meets the definition of a liquid or gas as per the definition of dangerous goods for transportation and to reduce evaporative emissions that contribute to ground-level ozone and diminish the effects of ozone-related health problems.

It is well known that RVP must be considered before put liquids into the pipeline for legal fulfilment and for pipeline and refinery safety.

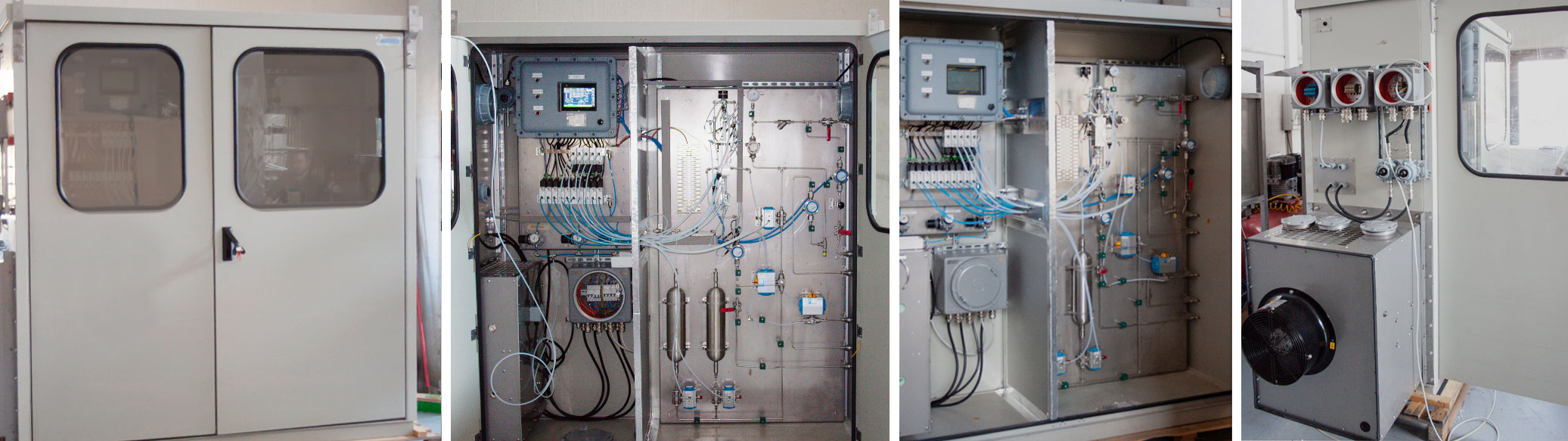

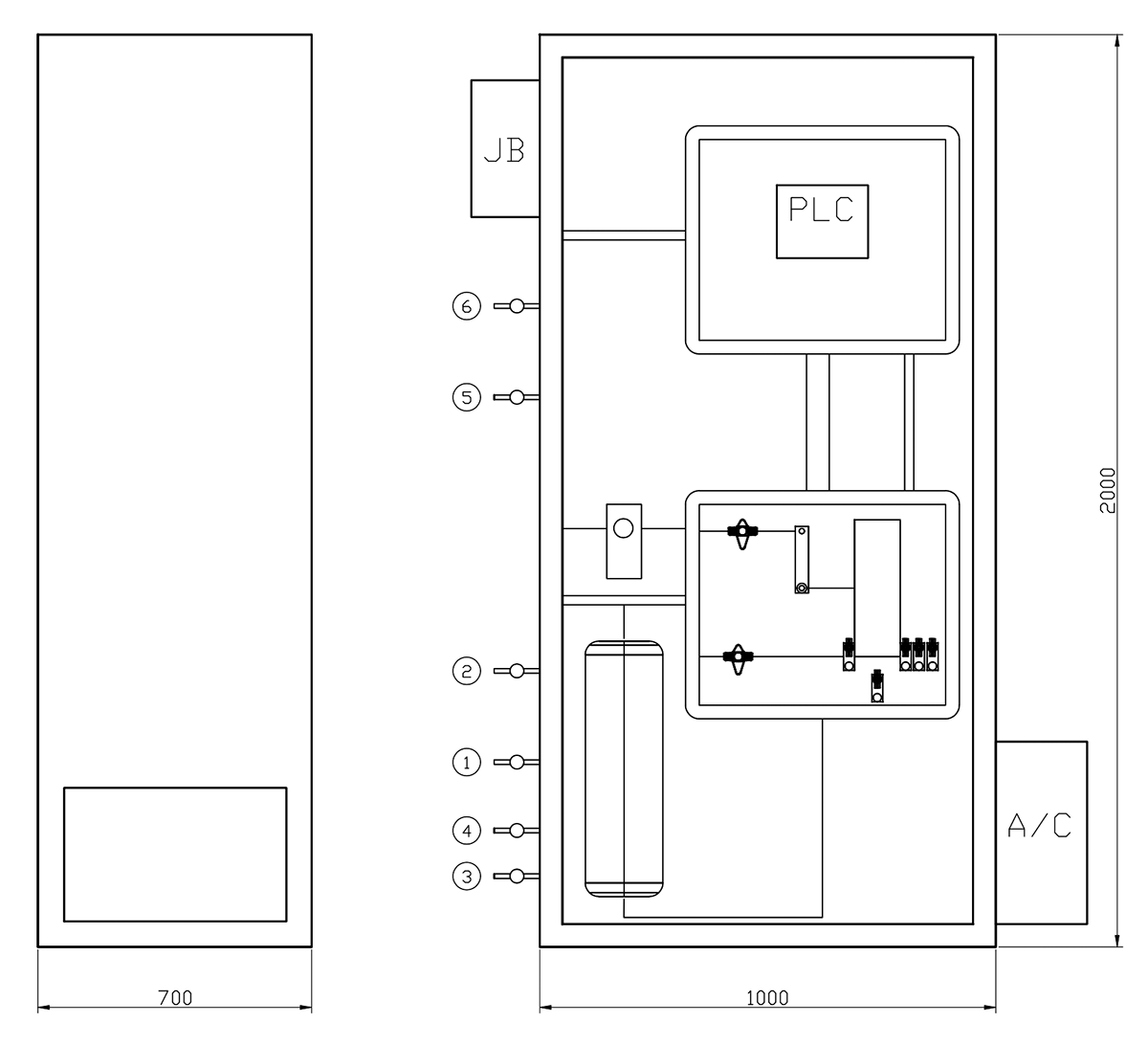

In this scenario, Linetronics OnLine 700 plays a fundamental role in every refinery, where it’s simple and rugged design supplies a reliable instrument for accurate and repeatable measurements.

It is ASTM D323 fully compliant, with a Siemens PLC that supervise all the operations and a Siemens Touch Panel for intuitive management and maintenance of the instrument.

The DCS communication is guaranteed by ModBus protocol in its RTU or TCP version depending on the customer’s requests.

It conforms to and extends Zone 2, IIB, T3 requirements.

The OnLine 700 has a fast-loop sampling valve that is linked to the measuring cell by a pressure reducer and a filter for a longer instrument life and to reduce maintenance.

The ASTM D323 standard foresees that vapor pressure apparatus is filled with a quantity of the sample and shaken until a constant pressure is observed.

This is achieved with a precision motor-controlled variable-size cell that permits the sample to flow assuring fresh sample for every test and create the exact volume ratio needed by the test.

The shake is driven by a Festo pneumatic actuator controlled by the PLC which constantly monitors the shaker action and the pressure inside the cell.

When a constant cell pressure is detected the reading, suitably corrected in temperature, is reported as the Reid vapor pressure.

The instrument performs an automatic-calibration with a CRM sample regularly on a user-customizable schedule.

Linetronic Technologies SA

Via Onorio Longhi 2 • 6864 Arzo • Mendrisio • Switzerland

tel. +41 91 630 07 03 • fax +41 91 630 07 19

email: info@lin-tech.ch