Laboratory and Process Analyzers

Automatic Analysers → NewLab Range • OilLab Range • Thermofat • OnLine Range

Filterability of Lubricating Oils • Ring and Ball • Foaming Tester • Oxidation Stability • Evaporation Bath • RBOT & TFOUT • RPVOT • Noack • Air Release • Pensky Martens • Leonardo Pensky Martens • Golleo Abel+Pensky • Aniline Point • Penetration • R.E.C.C. • Abel • Cleveland • Tag • Tag - 6901 • Reid Vapour Pressure • Ductilometer • Herschel Emulsifying • Saybolt Viscometer • Distillation

OilLab 525

Oxidation Stability of Gasoline and Aviation Fuels

ASTM D525

ASTM D873

ASTM D942

IP 40

EN ISO 7536

Subject

ASTM D525 - IP 40 - EN ISO 7536 - Oxidation Stability of Gasoline (Induction Period Method)

This test method covers the determination of the stability of gasoline in finished form only, under accelerated oxidation conditions.

ASTM D873 - Standard Test Method for Oxidation Stability of Aviation Fuels (Potential Residue Method)

This test method covers the determination of the tendency of aviation reciprocating, turbine, and jet engine fuels to form gum and deposits under accelerated aging conditions.

ASTM D942 - Oxidation Stability of Lubricating Greases by the Oxygen Pressure Vessel Method

This test method determines resistance of lubricating greases to oxidation when stored statically in an oxygen atmosphere in a sealed system at an elevated temperature under conditions of test.

OilLab 525/L

Automatic Oxidation Stability Bath, liquid version - 4 positions, ASTM D525, D873 and D942

- Compact structure painted with anti-acid epoxy products.

- Stainless steel bath with approx. 40 liters capacity, insulated and equipped with a stirring motor for grant temperature uniformity and side drain cock for atmospheric draining.

- Upper cover equipped with 4 holes for test cells accommodation, un-used positions can be covered with stand-by covers that prevents heat loss, the cover is made in stainless-steel for easy cleaning.

- Front opening useful for deposit the cells after test for cool down and bath medium drainage.

- Stainless steel electric heaters protected inside the bath by a double bottom stainless-steel protection.

- Linetronic Management software running on 12” High-brightness 800cd/m² TFT with resolution 1024 × 768:

- Pre-setting for method ASTM D525/ D873/ D942, or customizable analysis parameters;

- Settable bath temperature and controlled by PT100 A Class with 0,1°C precision, automatic for method selected or custom temperature;

- Calibration menu, result browser, dual level password protection;

- More than >60’000 analysis storage capacity;

- 2 × USB for connecting: mouse, keyboard and software updates;

- 1 x RJ45 Ethernet / Lims connection;

- Integrated beeper for end-test notification / errors;

- Oxygen sampling system with analog manometer and needle valve.

- Dedicated software for real time monitoring and recording that includes:

- Display of the pressure in bar / psi / Kpa;

- Graph creation in real time during the test;

- Invalid test indication in case of pressure leakage;

- Export of files in .xls / .pdf / .jpg format;

- Calibration up to 100 points.

Dimensions

- width 66 cm

- depth 60 cm

- height 45 cm

Weight

Power Supply

- 230 Vac or 115 Vac 50/60 Hz

Temperature Range

- ambient to +150°C or +302°F

- precision 0.1°C

Consumption

OilLab 525/ST-2

Automatic Oxidation Stability bath, dry version, 2 positions, ASTM D525, D873 and D942

- Compact structure painted with anti-acid epoxidy products.

- Single aluminium dry bath deeply coated, insulated and equipped with multi electrical heaters grant uniformity and stability.

- Upper cover equipped with 2 holes for test cells accommodation, un-used positions can be covered with stand-by covers that prevents heat loss, the cover is made in stainless-steel for easy cleaning.

- Linetronic Management software running on 8” High-brightness 800cd/m² TFT with resolution 1024 × 768:

- Pre-setting for method ASTM D525/ D873/ D942, or customizable analysis parameters;

- Single settable bath temperature and controlled by PT100 A Class with 0,1°C precision, automatic for method selected or custom temperature;

- Calibration menu, result browser, dual level password protection;

- More than >60’000 analysis storage capacity;

- 2 × USB for connecting: mouse, keyboard and software updates;

- 1 × RJ45 Ethernet / Lims connection;

- Integrated beeper for end-test notification / errors

- Export file in .xls format

- Dedicated software for real time monitoring and recording that includes:

- Display of the pressure in bar / psi / Kpa;

- Graph creation in real time during the test;

- Invalid test indication in case of pressure leakage;

- Export of files in xls. / .pdf / jpg. format;

- Calibration up to 100 points.

- Oxygen filling system with manual needle valve, analog manometer and filling tube, rear connection permit to joint to external Oxygen line (mandatory)

Dimensions

- width 34 cm

- depth 60 cm

- height 45 cm

Weight

Power Supply

- 230 Vac or 115 Vac 50/60 Hz

Temperature Range

- ambient to +150°C or +302°F

- precision 0.1°C

Consumption

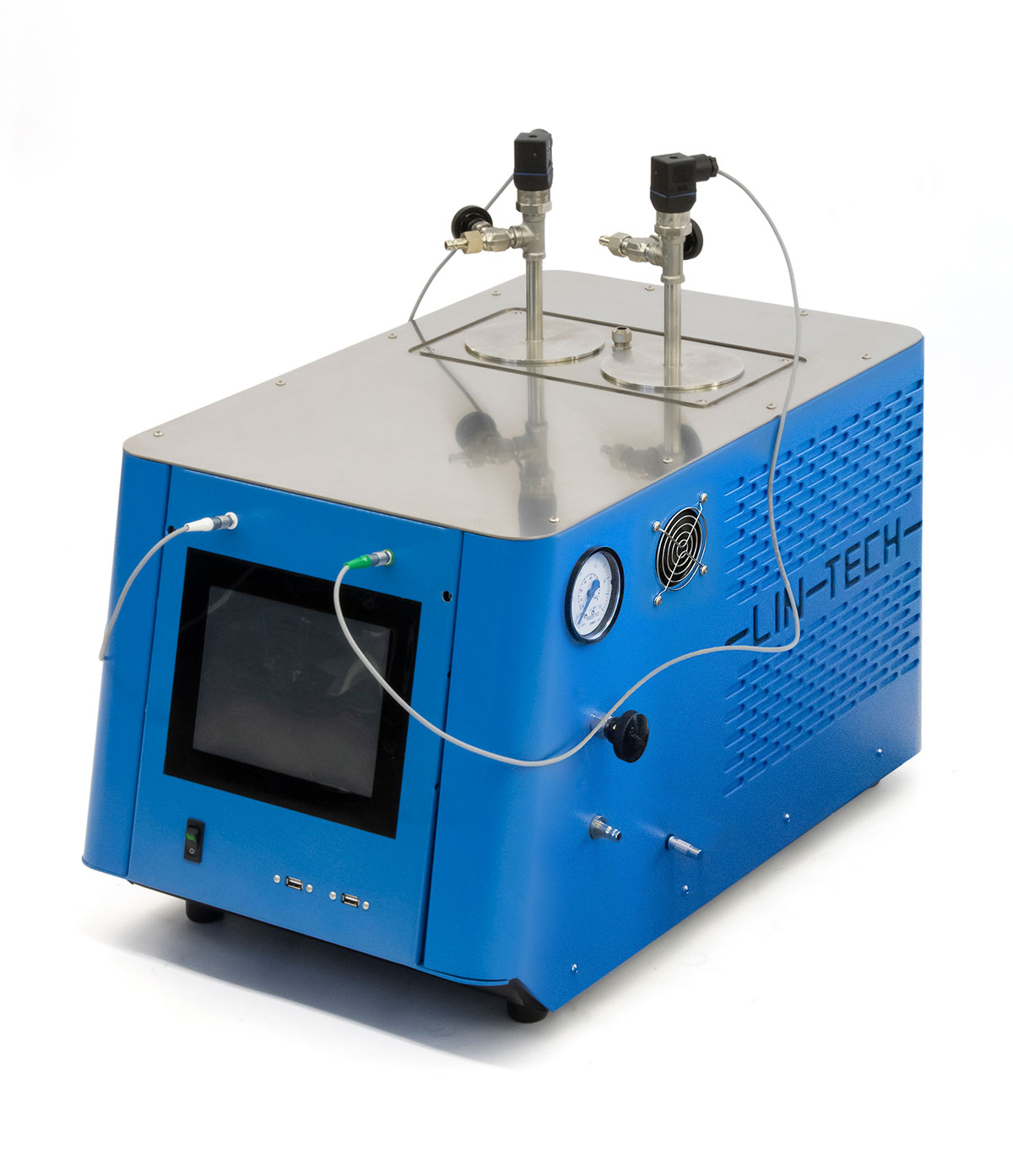

OilLab 525/ST-4

Automatic Oxidation Stability bath, dry version, 4 positions, ASTM D525, D873 and D942

- Compact structure painted with anti-acid epoxidy products.

- Double aluminium dry bath deeply coated, insulated and equipped with multi electrical heaters grant uniformity and stability.

- Upper cover equipped with 4 holes for test cells accommodation, un-used positions can be covered with stand-by covers that prevents heat loss, the cover is made in stainless-steel for easy cleaning.

- Front opening useful for deposit the cells after test for cool down.

- Linetronic Management software running on 8” High-brightness 800 cd/m² TFT with resolution 1024 × 768:

- Pre-setting for method ASTM D525/ D873/ D942, or customizable analysis parameters;

- Double settable bath temperature and controlled by PT100 A Class with 0,1°C precision, automatic for method selected or custom temperature;

- Calibration menu, result browser, dual level password protection;

- More than >60’000 analysis storage capacity;

- 2 × USB for connecting: mouse, keyboard and software updates;

- 1 × RJ45 Ethernet / Lims connection;

- Integrated beeper for end-test notification / error;

- Export file in .xls format.

- Dedicated software for real time monitoring and recording that includes:

- Display of the pressure in bar / psi / Kpa;

- Graph creation in real time during the test;

- Invalid test indication in case of pressure leakage;

- Export of files in xls. / .pdf / jpg. format;

- Calibration up to 100 points.

- Oxygen filling system with manual needle valve, analog manometer and filling tube, rear connection permit to joint to external Oxygen line (mandatory)

Dimensions

- width 34 cm

- depth 60 cm

- height 45 cm

Weight

Power Supply

- 230 Vac or 115 Vac 50/60 Hz

Temperature Range

- ambient to +150°C or +302°F

- precision 0.1°C

Consumption

Accessories for ASTM D525 – D873

1000183

1000183: Oxidation Pressure Vessel ASTM D525 - D873

- Complete of:

- Threaded suspension lid;

- Stem with filler rod and mounting flange;

- Needle valve for purging, pressurizing and exhausting pressure vessel with oxygen;

- Glass sample container with cover made in glass;

- Burst disc assembly set at 15 bar;

- Pressure transducer sensor.

- Interior of the pressure vessel can be easily cleaned to prevent corrosion.

- Threaded lid and vessel allow a tight closure.

1000536

1000536: Oxidation Pressure Vessel ASTM D525 - D873

- Complete of:

- Threaded suspension lid;

- Stem with filler rod and mounting flange;

- Needle valve for purging, pressurizing and exhausting pressure vessel with oxygen;

- Glass sample container with cover made in glass;

- Re-armable safety relief valve set at 15 bar;

- Pressure transducer sensor.

- Interior of the pressure vessel can be easily cleaned to prevent corrosion.

- Threaded lid and vessel allow a tight closure.

Spare Parts ASTM D525 - D873

- 2487: glass sample container with cover, pack of 2 pcs.

- 7064: gasket for vessel, pack of 10 pcs.

- 5432: needle valve for purging/discharging pressure vessel

- 16433: rupture disk set at 15 bar (only for 1000183 and 1000537)

Accessories for ASTM D942

15605-AUT

15605-AUT: Linetronic Oxidation Pressure Vessel - ASTM D942

- Pressure vessel made in stainless steel with threaded body.

- Complete of:

- Threaded suspension lid;

- Stem with mounting flange;

- Needle valve for purging, pressurizing and exhausting pressure vessel with oxygen;

- Holder and glass dishes;

- Pressure transducer sensor.

- Interior of the pressure vessel can be easily cleaned to prevent corrosion.

- Threaded lid and vessel allow a tight closure.

Spare Parts ASTM D942

- 5290: dish holder, 5 places, made in stainless steel

- 5292: sample dish, Pyrex®, 41 mm diameter, pack of 5 pcs.

- 7064: gasket for vessel, pack of 10 pcs.

Tools or Routine Calibration

- 3013: calibration decade box - PT100 Simulator

- 3102: kit of connectors and cables

- 3096: digital thermometer reader with LCD display for PT100, PT1000, resolution 0.01°C, accuracy 0.01°C, read up to +650°C

- 3774: PT100 sensor 3 mm diameter, 605 mm length, with connector

Linetronic Technologies SA

Via Onorio Longhi 2 • 6864 Arzo • Mendrisio • Switzerland

tel. +41 91 630 07 03 • fax +41 91 630 07 19

email: info@lin-tech.ch