Laboratory and Process Analyzers

Demulsibility and Foaming: Demulsibility Characteristics of Lubricating Oils • Foaming Characteristics of Lubricating Oils • Foaming Tendencies of Engine Coolants • Herschel Emulsifying

Foaming Characteristics

of Lubricating Oils

ASTM D892

DIN 51566

IP 146

Foaming Characteristics of Lubricating Oils.

This test method covers the determination of the foaming characteristics of lubricating oils at 24°C and 93.5°C. Means of empirically rating the foaming tendency and the stability of the foam are described.

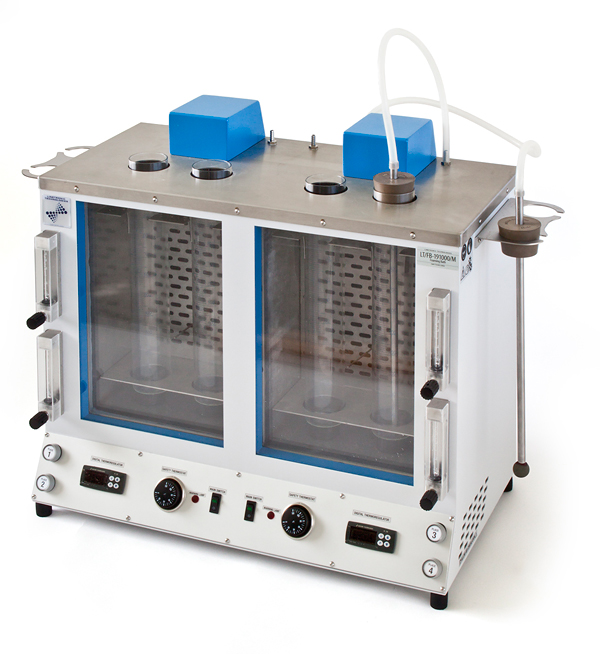

LT/FB-192000/M

Semi-automatic Apparatus for Foaming Characteristics of Lubricating Oils – 4 places

- Bench top instrument with metallic case structure painted with anti-acid products and double chamber insulation, top cover made in stainless steel with four holes for the cylinders accommodation and one hole for control thermometer (not included).

- 2 × independent 25 liters capacity stainless steel baths (one for 24°C and one for more than 93.5°C) equipped with viewing and illuminated windows, two independent motor stirrer grants uniformity and stability of bath temperature.

- Stainless steel grid divide the glassware from the heating and stirring device.

- Air pre-heating system by copper coils immersed in the first bath.

- Lateral stand-by support for stoppers and diffusing assembly.

- Anti-floating and centring system for test cylinders.

- Control unit include 7” Touch screen panel PC with 800 × 480 resolution with dedicated Lin-Tech software able to manage the bath functions:

- Independent management of 4 places analysis trough the activation of air micro-compressors and counter (time of blowing, waiting time, flow) – audible alarm for each intervention of the operator requested.

- Air flow monitoring system (flow rate) managed digitally and calibrated.

- Diagnostic panel for temperature calibration, air flow, analysis parameters.

- Removable back panel equipped with drain tap for easily empty and clean the baths.

- Baths are thermo-insulated equipped with tempered glass window inside for easily cleaning the limestone or oils residue, second protection panel made of plastic material with optical transparency.

- 4 Places Apparatus including: 4 diffuser stones (not certified), 4 rubber stoppers, 4 air diffuser tubes, 4 graduated cylinders.

Dimensions (cm)

- Width 71

- Depth 40

- Height 67

Power Supply

- 115 Vac or 220 Vac

- 50/60 Hz

LT/FB-191000/M

Manual apparatus for Foaming Characteristics of Lubricating Oils – 4 places

- Bench top instrument with metallic case structure painted with anti-acid products and double chamber insulation, top cover made in stainless steel with four holes for the cylinders accommodation and one hole for control thermometer.

- 2 × independent 25 Liters capacity Stainless steel baths (one for 24°C and one for more than 93.5°C) equipped with viewing and illuminated windows, two independent motor stirrer grants uniformity and stability of bath temperature.

- Stainless steel grid divide the glassware from the heating and stirring device.

- Air pre-heating system by copper coils immersed in the first bath.

- Lateral stand-by support for stoppers and diffusing assembly.

- Anti-floating and centring system for test cylinders.

- On the front the 4 flowmeter with regulating knob grant the easy adjustment of the air flow as foreseen by the method.

- Temperature controlled by 2 independent digital thermo-regulator with PID function, over-temperature protection and alarm, temperature displayed with 0,1°C precision thanks to PT100 Class A sensors.

- Stainless steel total immersion heating elements.

- 4 independent blowing pumps, equipped with damper system in order to avoid fluctuation in flow and external independent dryer system.

- Removable back panel equipped with drain tap for easily empty and clean the baths.

- Baths are thermo-insulated equipped with tempered glass window inside for easily cleaning the limestone or oils residue, second protection panel made of plastic material with optical transparency.

- 4 diffuser stones (not certified).

- 4 rubber stoppers.

- 4 air diffuser tubes.

- 4 graduated cylinders.

Dimensions (cm)

- Width 71

- Depth 40

- Height 67

Power Supply

- 115 Vac or 220 Vac

- 50/60 Hz

Accessories for LT/FB-191000/M and LT/FB-192000/M

- 7096: Certified diffuser stone.

- 5699: Mott metal cylindrical diffuser, tested and verified, ASTM D6082.

- 1000386: Mass flow meter.

- Flow mass range from 9 to 450 mL/min.

- Digital display readout.

- Connection joints ¼”.

- Power supply, battery or micro-USB power supply.

- Operating pressure 0.2, 11 bar.

- Made in anodized aluminium, Fkm seals.

- Repeatability ±0.5% of full scale.

- 7635: Desiccant for filters, pack of 700 gr.

- 5232: Apparatus for test maximum diameter / permeability of diffusers.

- Air compressor with filter.

- Air regulator and U-tube manometer.

- Glass calibrated cylinder with delivery tube.

- Filtering flask wide mouth with rubber stopper and delivery tube.

- Digital flowmeter 1.2 to 60 nL/min with calibration certificate.

- LAB-892-099: VL Reference liquid.

- Bottle of 1.0 liter approx.

- 1 year shelf life.

- Foam value acc. ASTM D892.

5232

Spare Parts for LT/FB-191000/M and LT/FB-192000/M

- 7094: Diffuser stone, not certified.

- 1206: Graduated cylinder 1000 ml.

- 7349: Rubber stopper, pack of 2 pcs.

- 3168: PT100 Probe.

- LAB-110-012: Heaters, pack of 2 pcs.

- 5547: Air-Inlet tube.

- 11241: Washer, pack of 2 pcs.

- 7635: Desiccant for filters, 450 g approx.

LT/FB-190000/M

Manual 2 Places - Twin Foaming Bath - ASTM D 892

- Bench top heavy glass tempered bath with 25 liters capacity.

- Stainless-steel cover with 2 × holes, 125 mm diameter, for introducing of graduated cylinders.

- One motor stirrer grants uniformity and stability of bath temperature.

- Stainless steel grid divides the glassware from the heating and stirring device.

- Air pre-heating system by copper coils immersed in the first bath.

- Anti-floating and centring system for test cylinders.

- On the front the 2 flowmeter with regulating knob grant the easy adjustment of the air flow as foreseen by the method.

- Temperature controlled by digital thermo-regulator with PID function, over-temperature protection and alarm, temperature displayed with 0,1°C precision thanks to PT100 Class A sensors.

- Stainless steel total immersion heating elements.

- 2 independent blowing pumps with relevant interrupters, equipped with damper system in order to avoid fluctuation in flow.

- 2 × glass graduated cylinder.

- 2 × stoppers.

- 2 × diffuser stone.

- 2 × diffuser tubes.

Power Supply

- 115 Vac or 220 Vac

- 50/60 Hz

Temperature Range

Consumption

Spare Parts for LT/FB-190000/M

- 7094: Diffuser Stone, not certified.

- 1206: Graduated cylinder 1000 ml.

- 7349: Rubber stopper, pack of 2 pcs.

- 3168: PT100 Probe.

- 3185: Heaters, pack of 2 pcs.

- 5547: Air-inlet tube.

- 11241: Washer, pack of 2 pcs.

Linetronic Technologies SA

Via Onorio Longhi 2 • 6864 Arzo • Mendrisio • Switzerland

tel. +41 91 630 07 03 • fax +41 91 630 07 19

email: info@lin-tech.ch