Laboratory and Process Analyzers

Automatic Analysers → NewLab Range • OilLab Range • Thermofat • OnLine Range

NewLab X • Cloud Point • CFPP • Pour Point • Freezing Point • Cloud and Pour Point • Filter Blocking Tendency • LTFT • Low-temperature Torque

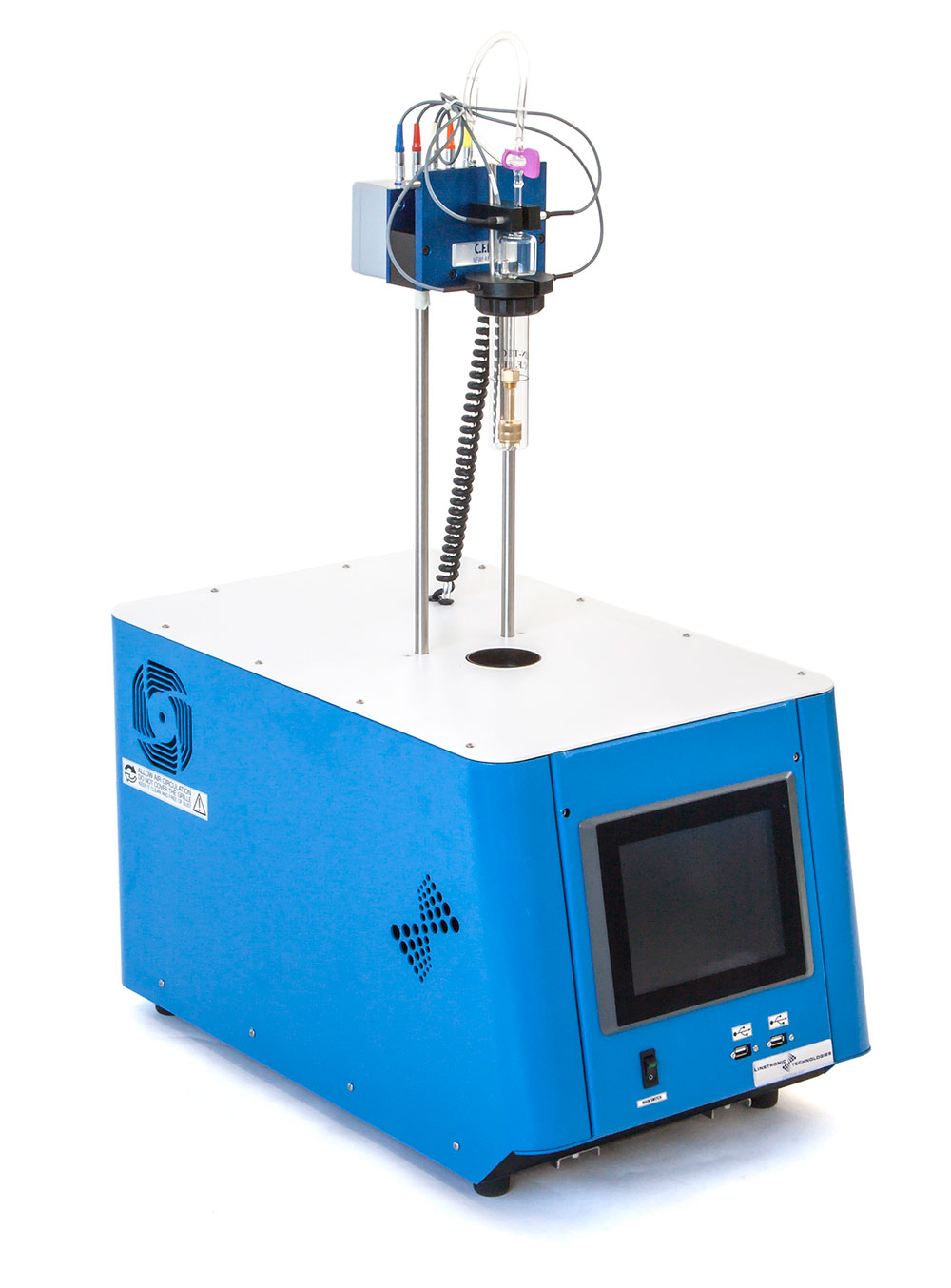

NewLab 200

CFPP

Cold Filter Plugging Point

ASTM D6371

IP 309 - IP 419

EN 116 - EN 16329

Cold Filter Plugging Point of diesel, biodiesel and heating fuels.

Measuring CFPP Principle

The sample is cooled down according to the methods and when the preselected temperature is reached a vacuum of 20 mBar is automatically applied to the sample. The product is sucked through the filter into the calibrated aspiration pipette. If the sample takes more than 60 seconds to reach the upper barrier detector (during the aspiration phase), or it fails to return completely into the test jar before that the product has cooled by a further 1°C, the Cold Filter Plugging Point is reached.

Measuring CFPP Devices

- Aspiration pipette

- Filter assembly

- Light barrier

Measuring Temperature Probe

- Platinum resistance PT100 class A

Accessories

OilLab 250 – external vacuum generator including:

- Vacuum pump

- Two glass bottles

- A glass cork with: u-tube, funnel, manual flow regulating valve

OilLab 255 – internal vacuum generator including:

- 1 x micro-pump of 350 mBar

- 1 x electronic pressure / vacuum regulator composed by: proportional valve, pressure / vacuum control sensor, regulator for reference vacuum generation at 20 mBar, vacuum stabilizer

Measuring Parameters

- Temperatures: in °C

- Measuring range: +80°C … -80°C

- Resolution: 0.06 °C

- Accuracy: ± 0.1 °C

- Repeatability / Reproducibility: as per standards methods or better

Software Features

New LabLink software able to manage up to 6 analytical heads simultaneously (stand alone)

- User friendly interface

- All analytical parameters recorded

- Customizable analysis parameters and methods

- Customizable results report

- Printable graphs and results

- Self-identification of the typology of the analysers connected

The software includes:

Analysis Menu

- Standard method as per ASTM / IP / ISO / EN / DIN… norms of reference

- Optional methods:

- T-sample – T-bath (Delta T constant)

- cooling rate °C / h

- selectable bath steps

- fast bath with selectable temperature

- Audible alarm and displayed messages at the end of the analysis and in case of errors and/or malfunctions

- The parameters displayed and updated in real time are:

- sample temperature

- bath temperature

- vacuum pressure

- low level light value

- up level light value

- aspiration time

- release time

- intertime test

Thanks to an istogram (graph) that shows the aspiration and release times it is possible to observe the behaviour of the sample during its cooling phase

This feature is an excellent tools for the observation and evaluation of the additivations actions and behaviour

Diagnostic Menu

- Direct access to all analog, digital, inputs and outputs

- Selectable value displaying: °C / Volt

- Vacuum data displayed in mBars

Calibration Menu

- Automatic calibration of each temperature probe

- Last calibration date referred to each single probe displayed and relative data printable

- Display of calibration diagram

- Insertion of offset values

- Standard and advanced calibration modes

Data Utilities

- Fields for introduction of operator and product name

- Archive viewer for files recall

- All analysis stored in Excel® compatible format

- Storage capacity for more than 60’000 analysis

- LIMS compatible

Integrated Touch Screen Panel PC

- TFT/LCD 12"

- Resolution 1024 × 768, 16.2 M colours

- 2 USB ports for connection to an external printer and/or external PC

- Storage capacity for more than 60'000 analysis

Cleaning pipette procedure

By using a suitable cleaning liquid and pressing the relevant function button the analyser performs a cleaning sequence of 10 aspirations cycles

Easy removing of aspiration pipette and filter assembly allows cleaning according to the methods

Test Jar

- Same dimensions and volume as described by the standard test methods

- Product level mark

- Small edge on the top in order to fix the glass cell to the analytical head

Cooling System

Integrated gas CFC free motor compressors:

- Single stage (for temperatures up to -40°C / 1)

- Double stage (for temperatures up to -80°C / 2)

Equipped with an automatic energy power save system. After 15 minutes from the end of the analysis the cooling system goes in stand-by mode.

Safety Devices

- Pressure controller for 1st stage motor compressor

- Pressure controller for 2nd stage motor compressor

- Thermostat for 2nd stage activation

- Thermo-switch for each cooling / heating jacket

- Motor compressors equipped with internal overload devices

Electrical Supply

- 220V ± 15% / 50 to 60 Hz

- 115V ± 15% / 60 Hz

Cord Cable

- 3 conductors flexible cable 2 m (7 feet) length with PVC sheath oil and heat resistant as per CENELEC directives

Ambient Temperature

| Dimensions (cm) |

1 test position |

2 test position |

3 test position |

4 test position |

6 test position |

| width |

66 |

66 |

100 |

134 |

130 |

| depth |

60 |

60 |

60 |

60 |

75 |

| height |

80 |

80 |

80 |

80 |

170 |

| Weight (kg) |

| single stage compressor |

70 |

90 |

- |

- |

- |

| double stage compressor |

80 |

100 |

130 |

160 |

280 |

NewLab 200 ST

- Cooling system ST:

- Integrated gas CFC free Stirling motor compressor

- For temperatures up to -110°C

- Integrated Touch Screen Panel PC for /ST configuration:

- TFT/LCD 8”

- Resolution 1024 × 768

- Measuring range: +55°C … -95°C

- Resolution: 0.01 °C

- Width: 34 cm

- Depth: 60 cm

- Height: 80 cm

- Weight: 34 kg

Spare Parts

- LAB-xxx/005-03: heater + auto adhesive + insulation

- LAB-xxx/005-04: thermo switch

- LAB-xxx/005-06: PT100 bath

- LAB-xxx/007-02: static relay

- LAB-xxx/007-04: PCB fuse 1.6 A, box of 10 pcs.

- LAB-xxx/006-01: cooling fluid valve + fitting

- LAB-200/002-02: vacuum valve + fitting

- LAB-200/007-01: main electronic board CFPP

- LAB-200/008-06: sensor up (orange)

- LAB-200/008-07: sensor down (yellow)

- LAB-200/008-08: emitter up (red)

- LAB-200/008-09: emitter down (blue)

- LAB-200/008-12: PT100 product w/connector

- LAB-200/008-04: CFPP calibrated glass cell

- LAB-200/008-041: o-ring for CFPP test jar

- LAB-200/008-13: calibrated aspiration pipette CFPP

- LAB-200/008-18: clamp + kness for vacuum tube

- LAB-200/013-01: filter assembly

- LAB-200/013-02: filter

- LAB-200/1288: o-ring (big) for CFPP filter

- LAB-200/1232: o-ring (small) for CFPP filter

Calibration Tools

- OilLab 80: calibration decade box – PT100 simulator

- OilLab 81: set of connectors and cables for cold range

Linetronic Technologies SA

Via Onorio Longhi 2 • 6864 Arzo • Mendrisio • Switzerland

tel. +41 91 630 07 03 • fax +41 91 630 07 19

email: info@lin-tech.ch