Laboratory and Process Analyzers

Sediments: Particulate Contamination in Aviation Fuels • Particulate Contamination in Middle Distillate Fuels • Sediment in Crude and Fuel Oils by Extraction • Total Sediment Tester

Particulate Contamination in Middle Distillate Fuels

ASTM D6217

Standard Test Method for Particulate Contamination in Middle Distillate Fuels by Laboratory Filtration.

This test method covers the determination of the mass of particulate contamination in a middle distillate fuel by filtration. This test method is suitable for all No. 1 and No. 2 grades in Specifications D396, D975, D2880 and D3699 and for grades DMA and DMB in Specification D2069.

2645

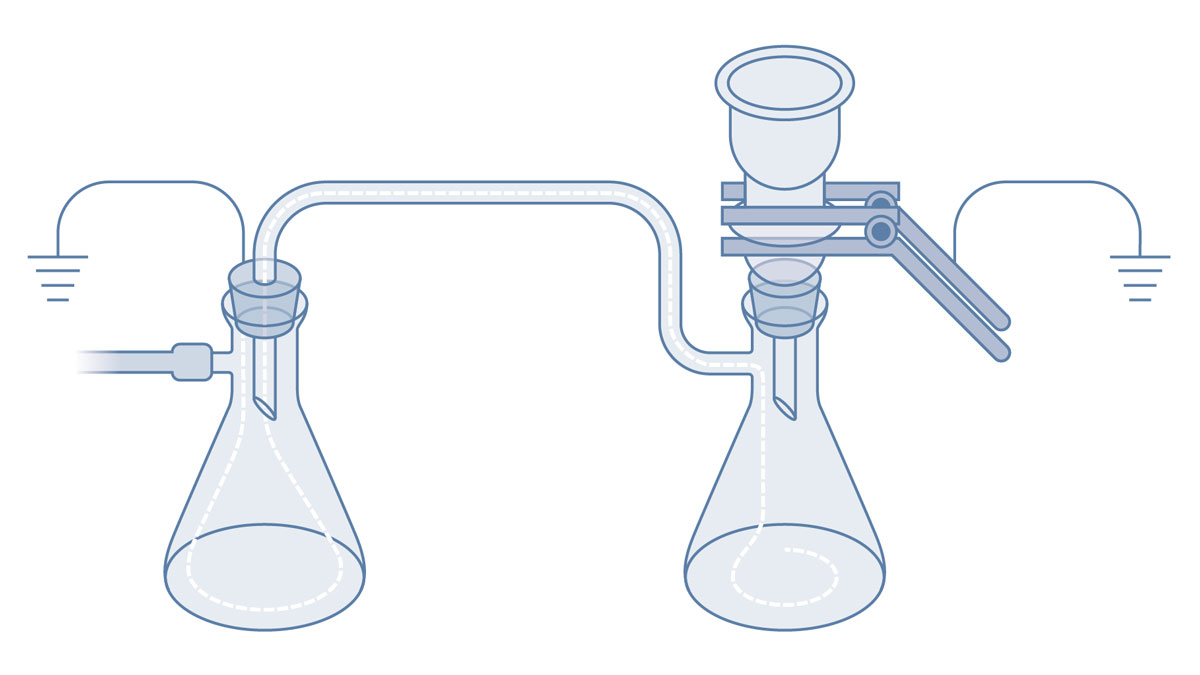

Manual Apparatus for Filter Assembly

- 2 × 2000 ml vacuum flask made of glass with side welded nozzle for filtrations under vacuum with rubber stopper, vacuum connection tube.

- Glass funnel set with filter support 47 mm and upper receiver with 250 ml graduated capacity.

- Double grounding system for connection to laboratory ground.

- Flat-bladed forceps for manage the filters.

- Nylon membrane filters, 47 mm diameter, nominal pore size of 0.8 µm.

- Graduated cylinders 100 ml and 1000 ml capacity.

- 18 pcs. of Petri Dishes with cover to protect the membrane filters.

Spare Parts

- 7537: Glass Petri dishes 60 × 12 mm, pack of 18 pcs.

- 7699: Nylon membrane filters, 47 mm diameter, nominal pore size of 0.8 µm, pack of 100 pcs.

- 2645-r: Set of 2 rubber stoppers with holes for ASTM D6217 apparatus.

Accessories

- 3794+: Diaphragm vacuum pump, for U.S. Air Force T.O. 42B-1-1 Jet Fuels filter test time.

- 100% oil-free transfer and maintenance-free.

- Pure transfer, evacuation and compression.

- Highly compatible with vapours and condensation.

- Chemically-resistant; therefore, suitable for highly aggressive or corrosive gases and vapours.

- Environmentally friendly.

- Delivery: 30 l/min.

- Ultimate vacuum: 100 mbar abs.

- Manual regulator with analog vacuum gauge 0-1200 mbar.

- Operating pressure: 0.5 bar g.

- Connectors for tube: ID 10 mm.

- Power Supply: 230 Vac 50 Hz - IP20.

- Weight: kg. 3.95.

- Dimensions: 36,1 × 14,1 × 10,2 cm.

- 1000462: Laboratory solvent dispenser.

- Wash capacity up to 1 lt.

- Filter container made in stainless steel 25 mm diameter.

- Filter 0.45 µm, 25 mm diameter (P/n 5237), pack of 100 pcs.

- Borosilicated glass flask.

- PTFE High quality seal.

- 5237: Omnipore PTFE filters, 25 mm diameter, 0.45 µm, pack of 100 pcs.

- 2596: Sampling container, 1 liter capacity, made of glass with screw cap, pack of 4 pcs.

- LT/DO-248000/N-8: Mini-oven.

- 8 liters capacity.

- Natural convection.

- For temperature from: +5 ambient up to +200°C.

- Power supply 220 Vac 50/60 Hz.

- 1000015: Semi Micro Analytical Balance.

- Capacity: 100 g.

- Linearity: ±0,03 mg.

- Response time: 6/8 sec.

- Calibration: internal.

- Division: 0,01 mg.

- Repeatability: ±0,03 mg.

- Pan diameter: 80 mm.

- LCD display with small decimal digits.

- Membrane keyboard, water proof and solvent resistant, easy to use with TARE, ON/OFF, PRINT and MENU.

- Indication of the reached stable weight.

- Bar-graph indicator of dosage and remaining capacity of the balance.

- Parameters configurable by menu: reading in g (grams), lb (pound), oz (ounce), ct (carats), pcs (pieces), % (percentage).

- Full scale automatic calibration with internal and/or external mass.

- Weighing underneath the balance.

- Selectable response time: "fast/slow".

- Data output: RS232 I/O adjustable.

- Operating temperature: 18° ÷ 35°C.

- Power supply: 230 Vac (-15/+20%) 50 Hz.

- Power consumption: 200 mA.

- Dimensions: 21,0 × 34,0 × 32,0 cm.

- Weighing chamber dimensions: 18,0 × 17,0 × 22,0 cm.

- Net weight: 6,6 kg.

3794+

1000462

LT/DO-248000/N-8

Linetronic Technologies SA

Via Onorio Longhi 2 • 6864 Arzo • Mendrisio • Switzerland

tel. +41 91 630 07 03 • fax +41 91 630 07 19

email: info@lin-tech.ch