Laboratory and Process Analyzers

Automatic Analysers → NewLab Range • OilLab Range • Thermofat • OnLine Range

RVP - Reid Vapour Pressure • Salts in Crude Oils

OnLine 900

Salts in Crude Oil

ASTM D3230

Standard Test Method for Salts in Crude Oil (Electrometric Method).

This test method covers the determination of the approximate chloride (salts) concentration in crude oil. The range of concentration covered is 3.5 mg/kg to 500 mg/kg or 1.0 lb/1000 bbl to 150 lb/1000 bbl (PTB) as chloride concentration/volume of crude oil.

This test method measures conductivity in the crude oil due to the presence of common chlorides, such as sodium, calcium, and magnesium. Other conductive materials may also be present in the crude oil.

Mixing system

The mixing system is composed by a motorized syringe fed by 6 tanks that are connected to a motorized 7 ways valve.

The valve selects the tank from wich the solvent is pulled an has a position for pushing to the cell through a calibrated pipe that contains the fresh sampl of oil.

Results

- The result is written as a 4..20mA linearized to 0 to 20PTB on 2 analog outputs (the second analog output marked as “ANALOG RESULT BACKUP” in electrical drawing is a duplicate of the first one has been foressen in case of fault of the first channel).

- The result is also written in register 40001 of modbus as a fixed point value.

- From modbus it is possible to access also the last 100 analysis of the instrument.

- Instrument is equipped with reundant Modbus RTU interface.

Alarm

- If the result is grater than 10PTB (Pounds per Thousands of Barrels).

- The alarm trigger can be configured via HMI on analysis options page.

Sampling system

- An internal fast loop provided with adequate pressure reducer and mutex filter to feed the analyzer.

- A slow loop after the fast loop outlet provides the right quantity of sample needed by the system.

- Material: SS316L

- Tubing 6 × 4 mm

Technical Specifications

- Measuring principle: Electrometric

- Detector: Conductivity cell

- Solvents:

- Solvent: Xylene

- Solvent Mixture: absolute Methanol/Butanol

- Cleaning Solution: Naphta

- Reagent containers:

- 3 × 12 litre for Methanol/Butanol, CRM and Blank

- 2 × 19 litre for rinse solution and Xylene carrier

- Reagents consumption: Approx. 1 litre /hr reagents + 1 litre/hr cleaning

- Measuring range: 0..20 PTB equivalent to: 0…57 mg/l

- Display: 7” with touch screen key board

- Electronic part: With supervisor PLC programmed

- Detection limit: \

- Accuracy: 5% of measurement, correlated to ASTM D3230

- Power supply: 230 V, 50 Hz

- Repeatability: 2%

- Power consumption: 500 W

- Cycle time: about 7 minutes + cleaning time

- Output:

- 1 × 4..20mA linear output

- 2 serial RS 485 Modbus

- Signaling /warnings: General fault, presence of H2S and/or HC inside the cabinet, maintenance request

- Sample volume: 20 cc/hour

- Sample flow: approx. 100 cc/min during sampling

- Alarm signal: High limit. Free configurable (desired set point 10PTB) equivalent to 29 mg/l

- Solids: max size 40 microns, amount less than 0,1 g/l

- Sample wetted parts materials in the instrument: Standard manufacturer

- Ambient temperature: 5… 56 °C.

- Sample inlet pressure: 2 bar max

- Sample discharge: Gravity outlet, atmospheric to drain

- Instrument air: 4-6 bar, clean, oil free and dry, consumption: max 100m³/hr

- Sample inlet temperature: max 62°C

- Area classification: Zone 2, Group IIB T4, EE x (p)

- Protection degree: IP 65/NEMA 4

- Cabinet: For outdoor installation with front door and inspection front window, H2S and HC sensors included in analysis and tanks cabinet.

- Cabinet material: SS316L

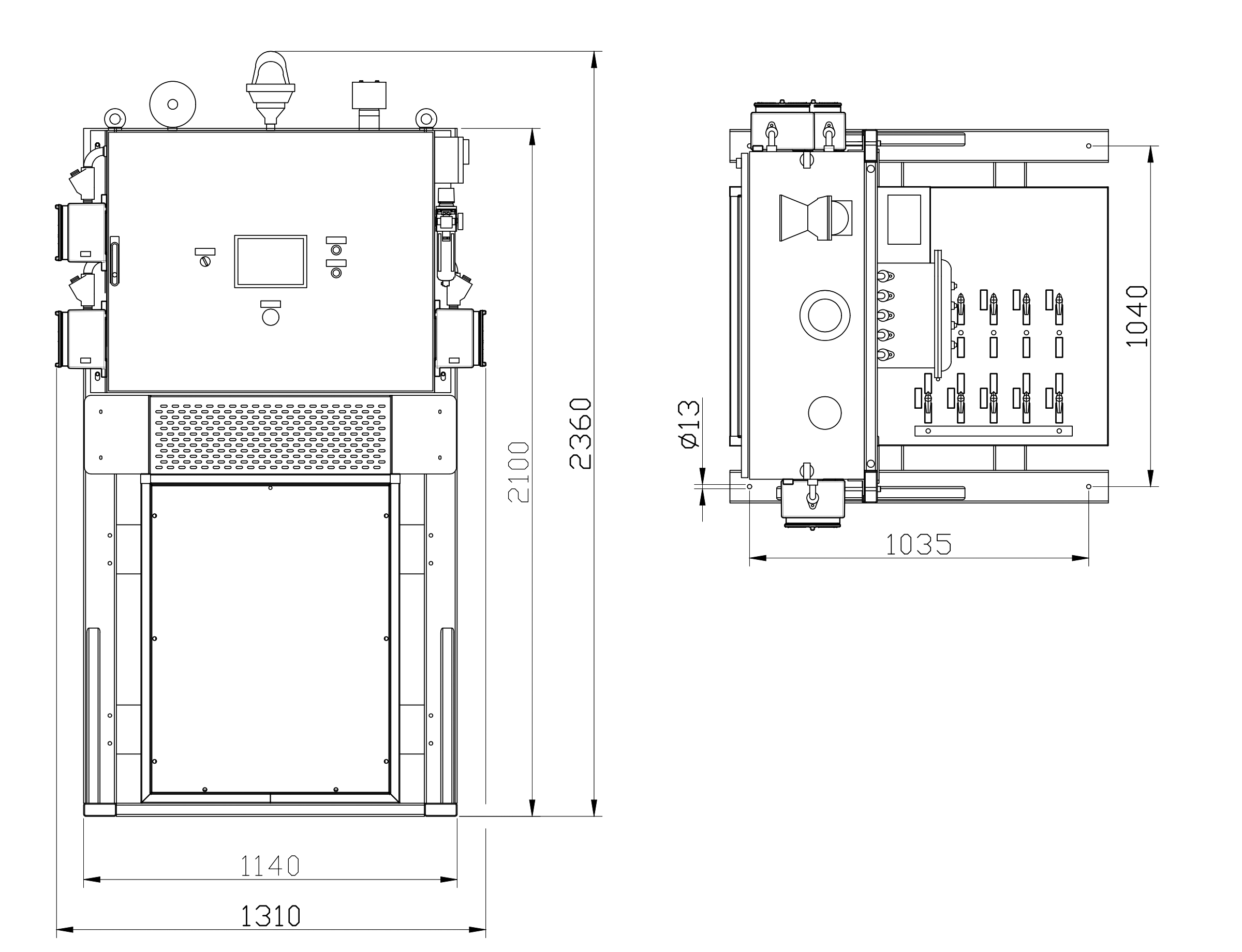

- Cabinet approx. dimensions: TBD

- Sample connections: Inlets and outlets ¼”

- Electrical connections: JB boxes EEx (d) on side wall

Sample return point

- Provided to return sample under pressure to the process, Material: SS316L

- Provided with shutoff valve and a ¼” connection

- Engineered for the process conditions

Linetronic Technologies SA

Via Onorio Longhi 2 • 6864 Arzo • Mendrisio • Switzerland

tel. +41 91 630 07 03 • fax +41 91 630 07 19

email: info@lin-tech.ch