Laboratory and Process Analyzers

Corrosion: Corrosion of Cast Aluminum • Copper / Silver Corrosion • Corrosiveness and Oxidation Stability • Metals Corrosion of Engine Coolants

Metals Corrosion of Engine Coolants

ASTM D1384

Corrosion Test for Engine Coolants in Glassware

This test method covers a simple beaker-type procedure for evaluating the effects of engine coolants on metal specimens under controlled laboratory conditions.

LT/MC-233000/M

Corrosion Test for Engine Coolants in Glassware

- Bench top instrument with steel structure painted with anti-epoxy products.

- Test bath made in spoutless tempered glass beaker with capacity 1000 mL equipped with Epdm stopper.

- Condenser made in glass, reflux straight type with a 400 mm condenser jacket.

- Aerator tube with porosity end size 12-C.

- Stainless steel heater 630 Watt with motor stirrer for granting stability and uniformity.

- Digital thermo-regulator display with PID temperature control and PT100 probe A Class for easily check the sample temperature.

- Support bar with clamps for glassware positioning.

- Analog flowmeter 0.8 - 8 nL/h with stainless-steel sheath and graduated glass metering chamber equipped with fine needle regulating knob.

Dimensions

Power Supply

- 230 Vac 50/60 Hz or 115 Vac

Temperature Range

Consumption

LT/MC-233003/M

Corrosion Test for Engine Coolants in Glassware (3 positions)

- Bench top instrument with steel structure painted with anti-epoxy products, internal bath with capacity of approx. 18 liters made in stainless steel with rounded edges and atmospheric drain for easily cleaning.

- Automatic levelling system of water (need connection to water line).

- 3 × test bath made in spoutless tempered glass beaker with capacity 1000 mL equipped with Epdm stopper.

- 3 × condenser made in glass, reflux straight type with a 400 mm condenser jacket.

- 3 × aerator tube with porosity end size 12-C.

- Stainless steel heater 800 Watt with overheat protection.

- Digital thermo-regulator display with PID temperature control and PT100 probe A Class for easily check the bath temperature.

- Support bar with clamps for glassware positioning.

- 3 × analog flowmeter 0.8 - 8 nL/h with stainless-steel sheath and graduated glass metering chamber equipped with fine needle regulating knob.

Dimensions

Power Supply

- 230 Vac 50/60 Hz or 115 Vac

Temperature Range

Consumption

LT/MC-233006/M

Corrosion Test for Engine Coolants in Glassware (6 positions)

- Bench top instrument with steel structure painted with anti-epoxy products, internal bath with capacity of approx. 18 liters made in stainless steel with rounded edges and atmospheric drain for easily cleaning.

- Automatic levelling system of water (need connection to water line).

- 6 × test bath made in spoutless tempered glass beaker with capacity 1000 mL equipped with Epdm stopper.

- 6 × condenser made in glass, reflux straight type with a 400 mm condenser jacket.

- 6 × aerator tube with porosity end size 12-C.

- Stainless steel heater 800 Watt with overheat protection.

- Digital thermo-regulator display with PID temperature control and PT100 probe A Class for easily check the bath temperature.

- Support bar with clamps for glassware positioning.

- 6 × analog flowmeter 0.8 - 8 nL/h with stainless-steel sheath and graduated glass metering chamber equipped with fine needle regulating knob.

Dimensions

Power Supply

- 230 Vac 50/60 Hz or 115 Vac

Temperature Range

Consumption

Accessories

- 3087: compact diaphragm air/vacuum pump

- Vacuum and Compression application

- Flow rate max. 5l/min

- Pressure max. 0.3 bar rel.

- Ultimate Vacuum max. 300 mbar (abs.)

- Weight 0.85 Kg

- Dimensions 72 × 72 × 180 mm

- Valve Material NBR coated

- 4 mm connector included

- Maintenance free

- Power Supply 220 Vac 50-60Hz

Accessories for Each Test Position

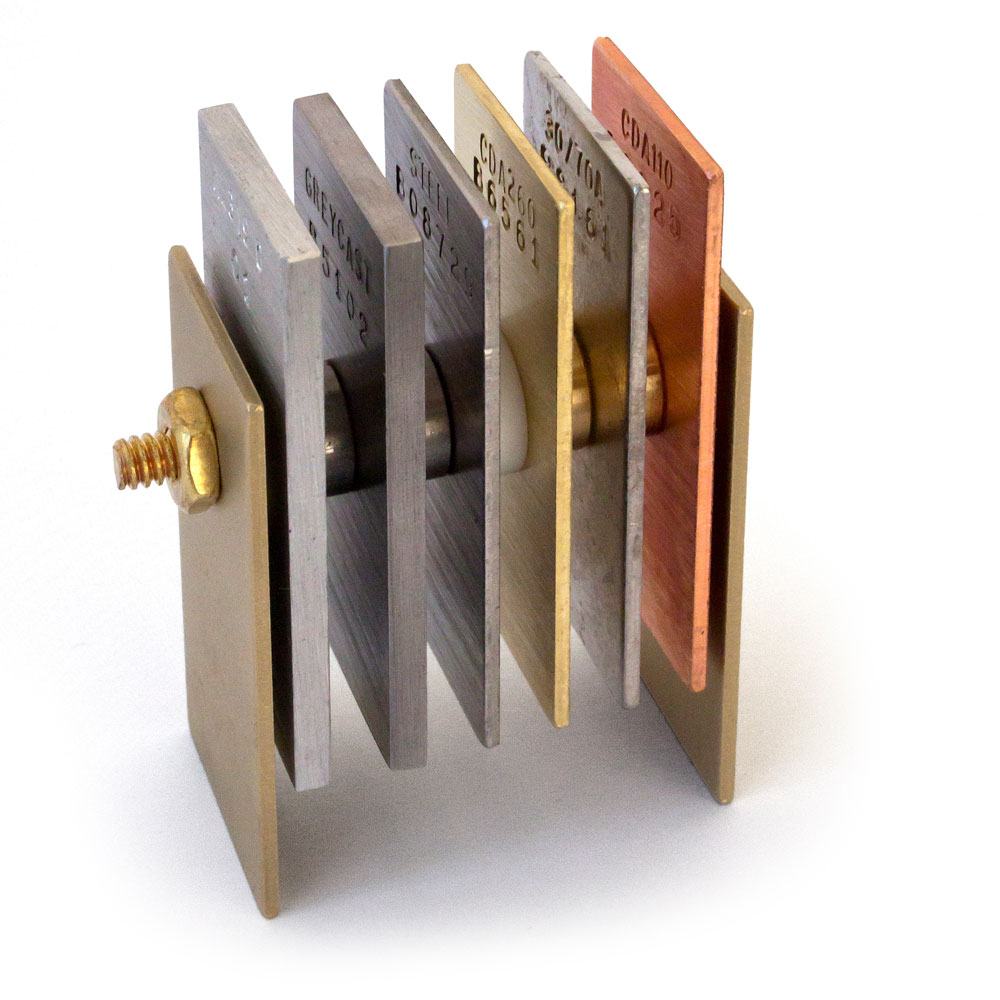

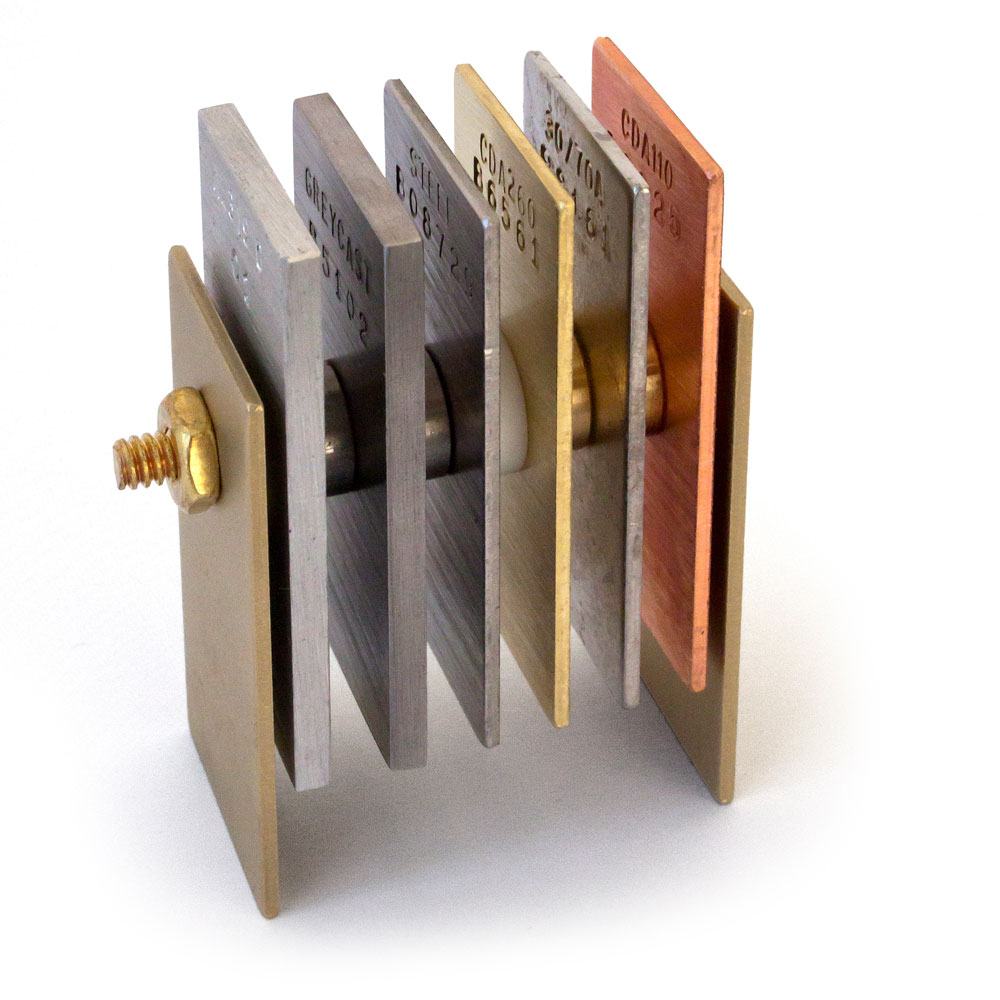

- 7134: catalyst ASTM D1384 metal specimen arrangement

- 2 × brass leg, pan head screw with hex nut

- insulating spacers (brass, steel and Ptfe)

- test speciments 50.8 × 25.4 × 3.18 mm made of:

Copper CA-110

Solder 30%

Brass CA-260

Steel SAE-1020 CR

Cast Iron SAE G-3500

Cast Aluminum A319

7134

Mandatory Accessories for Each Test Position – Liquid Bath

- T-AS1C: thermometer ASTM 1C

- 3837: digital thermometer reader with LCD display for PT100, PT1000

- resolution 0.01°C

- accuracy 0.01°C

- read up to +650°C, double channel

- 3779: PT100 sensor for immersion

- temperature range -196…+500°C

- 3 mm diameter

- 300 mm length

Spare Parts

Recommended for 2 years for each test position

- 2211: flowmeter with needle valve, range 0.8 – 8 nL/h

- 1248: beaker 1 Liter capacity with rubber stopper

- 2185: Liebig condenser 400 mm, pack of 3 pcs.

- 1251: tube for air diffusion with porosity ended (P2)

- 16265: holder set

- pan head screw

- hex nut

- brass leg

- insulating spacers (brass, steel and Ptfe)

- 7121: metal specimen Copper, spare parts for 7134, pack of 5 pcs.

- 7123: metal specimen Solder, spare parts for 7134, pack of 5 pcs.

- 7125: metal specimen Brass, spare parts for 7134, pack of 5 pcs.

- 7127: metal specimen Steel, spare parts for 7134, pack of 5 pcs.

- 7129: metal specimen Cast Iron, spare parts for 7134, pack of 5 pcs.

- 7130: metal specimen Cast Aluminum, spare parts for 7134, pack of 5 pcs.

Linetronic Technologies SA

Via Onorio Longhi 2 • 6864 Arzo • Mendrisio • Switzerland

tel. +41 91 630 07 03 • fax +41 91 630 07 19

email: info@lin-tech.ch