Laboratory and Process Analyzers

Additional Instruments • Aniline • Bitumen • Blends • Calorimetry • Centrifuge • Cold Behaviours • Colourimetry • Corrosion • Demulsibility and Foaming • Densimetry • Distillation • Flash Point • Gum - Rubber • Hydrometers • LPG • Lubricating Greases and Oils • Oxidation • Penetration • Residues • Rust • Sediments • Sulfur • Thermometers • Vapour Pressure • Viscosimetry • Water • Wax

Centrifuge

ASTM D91, ASTM D96, ASTM D893, ASTM D1796, ASTM D2273, ASTM D2709, ASTM D2711, ASTM D4007, ASTM D5546,

API 2542, API 2548, BS 4385, DIN 51793, IP75, IP 359, ISO 3734, ISO 9030, NF M07-020

ASTM D91 - Precipitation Number of Lubricating Oils

This test method covers the determination of the precipitation number of steam cylinder stocks and black oils, and can be used for other lubricating oils.

ASTM D96 (obs.) - Water and Sediment In Crude Oil

This test method covers the centrifuge method for determining sediment and water in crude oil during field custody transfers.

ASTM D893 - Insolubles in Used Lubricating Oils

This test method covers the determination of pentane and toluene insoluble in used lubricating oils.

ASTM D1796 - Water and Sediment in Fuel Oils

This test method covers the laboratory test for determination of water and sediment in fuel oils by using the centrifuge method in the range from 0 to 30 % volume.

ASTM D2273 - Trace Sediment in Lubricating Oils

This test method covers the determination of trace amounts (less than 0.05 volume %) of sediment in lubricating oils.

ASTM D2709 - Water And Sediment in Middle Distillate Fuels

This test method covers the determination of the volume of free water and sediment in middle distillate fuels having viscosities at 40°C (104°F) in the range of 1.0 to 4.1 mm/s (1.0 to 4.1 cSt) and densities in the range of 770 to 900 kg/m.

ASTM D2711 - Demulsibility Characteristics of Lubricating Oils

This test method covers the measurement of the ability of oil and water to separate from each other. It is intended for use in testing medium and high-viscosity lubricating oils.

ASTM D4007 - Water and Sediment in Crude Oil

This test method describes the laboratory determination of water and sediment in crude oils by means of the centrifuge procedure.

ASTM D5546 - Standard Test Method for Solubility of Asphalt Binders in Toluene by Centrifuge.

This test method covers determination of the degree of solubility of asphalt binders in toluene using centrifugal separation. The method is an alternative to Test Method D 2042, and may be preferable to Test Method D 2042 when testing modified asphalt binders.

LT/CF-121000/M

Laboratory Centrifuge

- Table top compact and robust centrifuge, frontal and upper part made of anti-abrasion and fire-retardant plastic material.

- Sever method available: ASTM D91, D893, D2273, D2709, D5546, API 2542, API 2548, BS 4385, DIN 51793.

- TFT color touch screen, visible from more than 3 m.

- Shows RPM and RCF, time, temperature, acceleration/deceleration values (PCBS) and unbalancing location system (ULS).

- Speed programming in 10 RPM/10 xg steps.

- Real RCF values on screen based in accessories configuration.

- Count up/down from “0” or at “set RPM/RCF” for test reproducibility, timer countdown/up from “0” or at “set RPM/ RCF” for reproducible tests, timer settable from 1min – 99 hrs.

- PCBS: Progressive controlled acceleration and braking system up to 175 selectable ramps that prevents sample homogenization after separation.

- ULS: Unbalancing location system indicating on the screen the number of the bucket which produces the unbalance switch off.

- 40 programmable memories, with protection under password.

- Several acoustic and visual messages warning the user the device situation.

- Microprocessor controlled, PC connection, last values remain in memory.

- Induction motor maintenance free (brushless) with noise level below 60 dB, Rotors and adapters list on memory.

- Start, stop, open lid and short spin with adjustable speed buttons.

- Option of free/locked adjustment of RPM/ RCF along the run.

- Automatic rotor recognition, over-speed protection.

- Automatic lid lock system, motorized with double lock.

- Emergency lid-lock release.

- Locking and protection against opening along the run.

- Lid dropping protection.

- Port in the lid for calibration and operation checking.

- Chamber of centrifugation in stainless steel (easy cleaning), equipped with protection safety ring.

- Rotors and adapters autoclavable, easy to install by the user.

- Automatic disconnection for energy saving up to 8 h.

- Max speed 3000 RPM / 2425 RCF xg.

- Swing out rotor 4 positions – for hold 4 × 100 ml 8/6” tubes.

Power Supply

- 220 or 115 Vac, 50/60 Hz

- 450 W

Dimensions

Weight

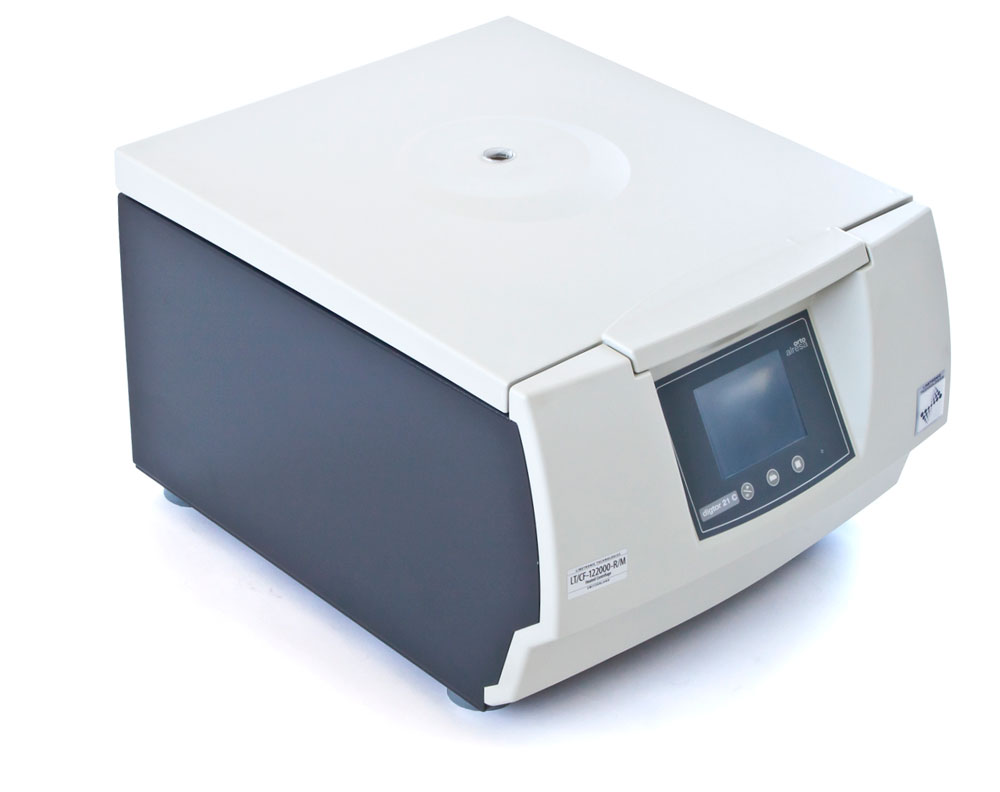

LT/CF-122000-R/M

HeatedLaboratory Centrifuge

- Table top compact and robust centrifuge, frontal and upper part made of anti-abrasion and fire-retardant plastic material.

- Sever method available: ASTM D91, D96, D893, D1796, D2273, D2709, D2711, D4007, D5546, API 2542, API 2548, BS 4385, ISO 3734, ISO 9030, IP75, IP 359, NF M07-020, DIN 51793.

- TFT color touch screen, visible from more than 3 m.

- Shows RPM and RCF, time, temperature, acceleration/deceleration values (PCBS) and unbalancing location system (ULS).

- Speed programming in 10 RPM/10 xg steps.

- Real RCF values on screen based in accessories configuration.

- Count up/down from “0” or at “set RPM/RCF” for test reproducibility, timer countdown/up from “0” or at “set RPM/ RCF” for reproducible tests, timer settable from 1min – 99 hrs.

- PCBS: Progressive controlled acceleration and braking system up to 175 selectable ramps that prevents sample homogenization after separation.

- ULS: Unbalancing location system indicating on the screen the number of the bucket which produces the unbalance switch off.

- 40 programmable memories, with protection under password.

- Several acoustic and visual messages warning the user the device situation.

- Microprocessor controlled, PC connection, last values remain in memory.

- Induction motor maintenance free (brushless) with noise level below 60 dB, rotors and adapters list on memory.

- Start, stop, open lid and short spin with adjustable speed buttons.

.

- Option of free/locked adjustment of RPM/ RCF along the run.

- Automatic rotor recognition, over-speed protection.

- Lid provided with security systems:

- Automatic lid lock system, motorized with double lock.

- Emergency lid-lock release.

- Locking and protection against opening along the run.

- Lid dropping protection.

- Port in the lid for calibration and operation checking.

- Chamber of centrifugation in stainless steel (easy cleaning), equipped with protection safety ring that also reduce heat dissipation.

- Rotors and adapters autoclavable, easy to install by the user.

- Automatic disconnection for energy saving up to 8 h.

- Preheating program with rotor spinning and temperature selectable. Allows keep the chamber at working temperature before starting the process.

- Regulation of the room temperature +5°C (41°F) to 80°C (176°F) in 1°C/1°F steps programmable in °C o °F.

- Temperature sensor inside the chamber. Overheating protection.

- Max speed 3000 RPM / 2425 RCF xg.

- Swing out rotor 4 positions – for hold 4 × 100 ml 8/6” tubes.

Power Supply

- 220 or 115 Vac, 50/60 Hz

- 450 W

Dimensions

Weight

Accessories for Safety

LAB-4007-010: Gas Release and Dilution System

- Safety box system that work only when centrifuge is in analysis.

- Create 10 l/min suction from test chamber (compressed air supply is requested / max 8 bar).

- Air inlet pressure regulator and inlet pressure gauge.

- Operation controlled by operator with a simple valve.

LT/WB-123200/M: Water Conditioning Bath 18 Liters Capacity

- Heating element bottom positioned.

- Atmosferic drain tap.

- Stainless steel inner tank with rounded edges.

- Digital thermoregulatory with 0.1°C precision.

- Stainless steel cover with handle.

- Dimensions 36 × 37 × 33 cm.

- Power supply 220 Vac or 115 Vac.

Accessories

| ASTM |

optional

accessories | LT/WB-123000/M

water bath | D91 | D96 | | D1796 | D2273 | D2709 | | D4007 | |

LT/DO-248000/F

drying oven | | | D893 | | | | | | D5546 |

LT/B-2470/BC150

analytical balance | | | D893 | | | | | | D5546 |

LAB-4007-010

Gas release and dilution system | | | | | | | | D4007 | |

| adapters | 5116

adapter made in plastic

with rubber insert,

height 137 mm,

pack of 4 pcs.

for 2104 and 2106 | D91 | D96 | D893 | D1796 | D2273 | D2709 | D2711 | D4007 | D5546 |

5419

adapter made in plastic

with rubber insert,

height 65 mm,

pack of 4 pcs.,

for 2102 and 2109 | | D96 | | | | D2709 | D2711 | | |

5420

adapter made in plastic

with rubber insert,

height 137 mm,

pack of 4 pcs.,

for 2108 | | D96 | | | | | D2711 | | |

5421

adapter made in plastic

with 7 positions

height 97 mm

pack of 4 pcs.

for 2110 | | D96 | | | | | | | |

| glassware | 2102

pear-shaped tube

100 ml

graduated to 0.1 ml

pack of 4 pcs. | | D96 | | | | D2709 | D2711 | | |

2102/st

stoppers, pack of 50 pcs. | | | | | | | | | |

2104

cone-shaped tube

100 ml

height 203 mm

graduated to 0.05 ml

pack of 4 pcs. | D91 | D96 | D893 | D1796 | | | D2711 | D4007 | D5546 |

2104/st

stoppers, pack of 50 pcs. | | | | | | | | | |

2106

trace sediment tube

100 ml

graduated to 0.005 ml

fine tip

pack of 4 pcs. | | | | | D2273 | D2709 | D2711 | | |

2106/st

stoppers, pack of 50 pcs. | | | | | | | | | |

2108

cone-shaped tube

100 ml

height 152 mm

graduated to 0.05 ml

pack of 4 pcs. | | D96 | | | | | D2711 | | |

2108/st

stoppers, pack of 50 pcs. | | | | | | | | | |

2109

trace sediment

pear-shaped

tube Goetz 100 ml

with stopper

pack of 4 pcs. | | | | | | D2709 | | | |

2110

Api tube 12.5 ml

with % graduation

pack of 12 pcs. | | | D893 | | | | | | |

2110/st

stoppers, pack of 50 pcs. | | | | | | | | | |

| racks | 5425

5 places water bath rack

for 2102 and 2109 | | D96 | | | | D2709 | D2711 | | |

5473

8 places water bath rack

or 2104 and 2106 | D91 | D96 | D893 | D1796 | D2273 | D2709 | D2711 | D4007 | D5546 |

5474

6 Places water bath rack

for 2108 | | D96 | | | | | D2711 | | |

LAB-101-228/W28

28 Places water

bath rack for 2110 | | D69 | | | | | | | |

LT/WB-123200/M - water conditioning bath, 18 liters capacity, LAB-4007-010 - gas release and dilution system, adapters and glassware.

Linetronic Technologies SA

Via Onorio Longhi 2 • 6864 Arzo • Mendrisio • Switzerland

tel. +41 91 630 07 03 • fax +41 91 630 07 19

email: info@lin-tech.ch