Laboratory and Process Analyzers

Automatic Analysers → NewLab Range • OilLab Range • Thermofat • OnLine Range

Filterability of Lubricating Oils • Ring and Ball • Foaming Tester • Oxidation Stability • Evaporation Bath • RPVOT (570) • RPVOT (571) • Noack • Air Release • Pensky Martens • Leonardo Pensky Martens • Golleo Abel+Pensky • Aniline Point • Penetration • R.E.C.C. • Abel • Cleveland • Tag • Tag - 6901 • Reid Vapour Pressure • Ductilometer • Herschel Emulsifying • Saybolt Viscometer • Distillation

OilLab 510 - Foaming Tester

ASTM D892

ASTM D6082

DIN 51566

IP 146

ISO 6247

Subject

Foaming characteristics of lubricating oils: this test method covers the determination of the foaming characteristics of lubricating oils at 24°C and 93.5°C. Means of empirically rating the foaming tendency and the stability of the foam are described.

Main Features

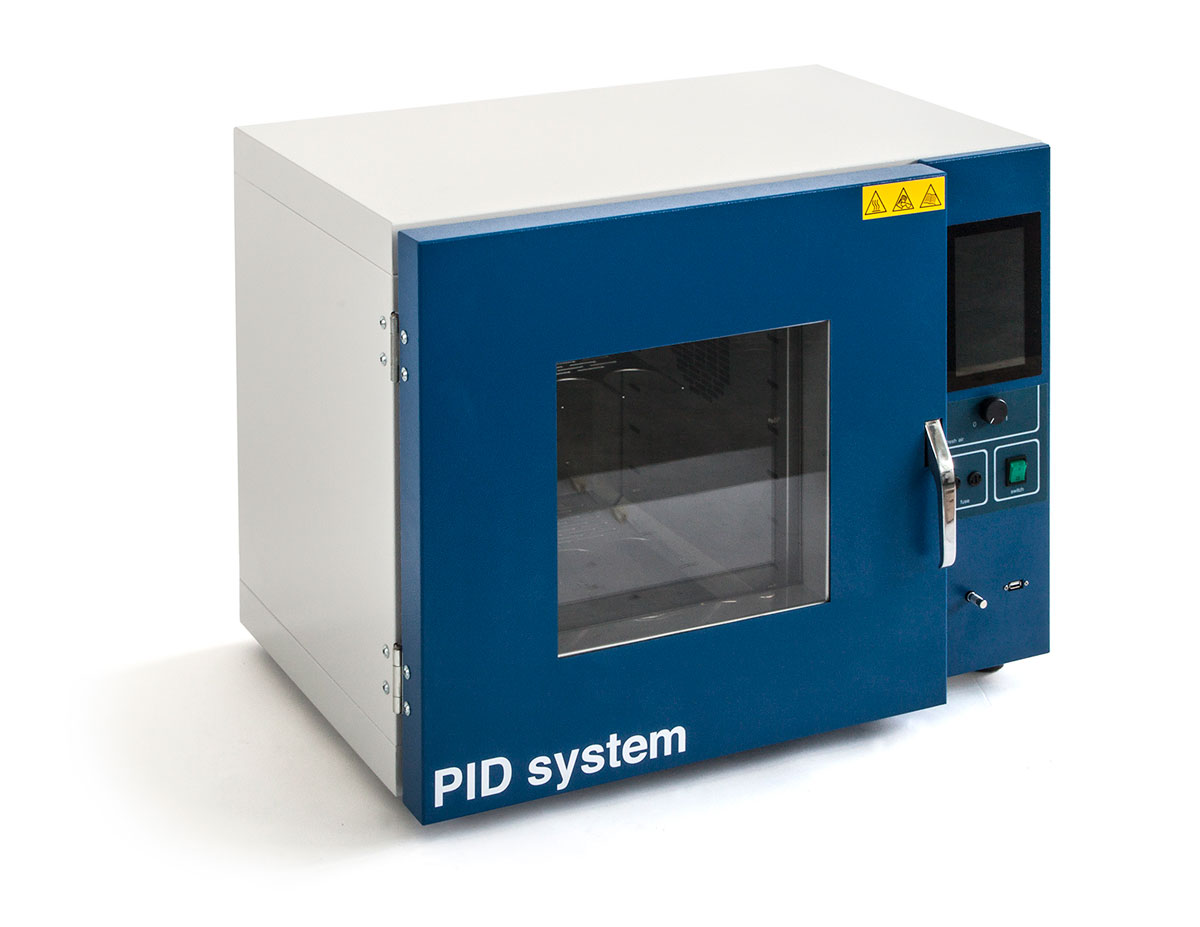

- Four test position heated air bath for measuring the foaming tendencies of lubricating oils in the temperature range of +20 to +150°C.

- Compact and robust analyzer painted with epoxy paint.

- Automatic analyser as for ASTM D892 and ASTM D6082.

- The electronic board grant the digital display of the signals with a resolution of 0.01 and precision of ± 0.1°C.

- Long temperature probe is positioned for digital control and test sample temperature and precise temperature control during the foaming process.

- 4 independent micro pump and 4 independent digital airflow meter indicating mass air flow with automatic flow controllers are used for precisely measuring and controlling the amount of air delivered to the air diffuser.

- The airflow is controlled at either a rate of 94 or 200 ±5 mL/min, depending if testing by ASTM D892 or D6082, respectively.

- The parameters are displayed during the test on the touch screen allows the operator selection and full adjustment of all test parameters.

- The labLink software include operator name , filename, 4 independent analysis, diagnostic and calibration menu.

- A multi-pane insulated window allows full view of the test cylinder for observation of the foam.

- The unit is supplied with the built in cooling system made by integrated Peltier modules (LAB-510-18-01) able to maintain the chamber temperature below +24°C.

- Internal rack able to accommodate 4 test cylinder with warm light.

- The 7” PC with resolution of 480 x 800, 1 × usb port, equipped with the Lablink software with both ASTM D892 and D6092 test methods, for automatic start /stop soak time, audible alarm after completing soak time.

- Precision as per test method requirements: ±0.5°C.

- Equipment precision: ±0.1°C.

- Temperature display definition: 0.01°C.

- Max temperature as per test method requirements: 150°C.

- Equipment maximum temperature: 180°C, in controlled lab temperature environment.

Integrated Touch Screen Panel PC

- TFT/LCD 7”

- Resolution 480 × 800

- 1 USB port

Software

- Real time display of all the analytical parameters

- Automatic calibration of each temperature probe by means of the calibration decade box

- Storage of the data referred to the calibration

- Last calibration date referred to each single probe displayed

- Access to all analogue and digital signals (inlet and outlet) in order to verify their functioning.

Electrical Supply

- 220V ± 15% / 50 to 60 Hz

- 115V ± 15% / 60 Hz

Dimensions

- width 75 cm

- depth 61 cm

- height 61 cm

Weight

Accessories

- LAB-101-883: diffuser stone (not certified)

- LAB-101-887: mott metal cylindrical diffuser (tested and verified) – ASTM D6082

Spare Parts

- LAB-101-883: diffuser stone (not certified)

- LAB-101-880: graduated cylinder 1000 ml

- LAB-101-882: rubber stopper, pack of 2 pcs.

- LAB-140-002: PT100 probe

- LAB-150-015: static relay

- LAB-101/08-66: thermal fuses

Linetronic Technologies SA

Via Onorio Longhi 2 • 6864 Arzo • Mendrisio • Switzerland

tel. +41 91 630 07 03 • fax +41 91 630 07 19

email: info@lin-tech.ch