Laboratory and Process Analyzers

Automatic Analysers → NewLab Range • OilLab Range • Thermofat • OnLine Range

Filterability of Lubricating Oils • Ring and Ball • Foaming Tester • Oxidation Stability • Evaporation Bath • RPVOT (570) • RPVOT (571) • Noack • Air Release • Pensky Martens • Leonardo Pensky Martens • Golleo Abel+Pensky • Aniline Point • Penetration • R.E.C.C. • Abel • Cleveland • Tag • Tag - 6901 • Reid Vapour Pressure • Ductilometer • Herschel Emulsifying • Saybolt Viscometer • Distillation

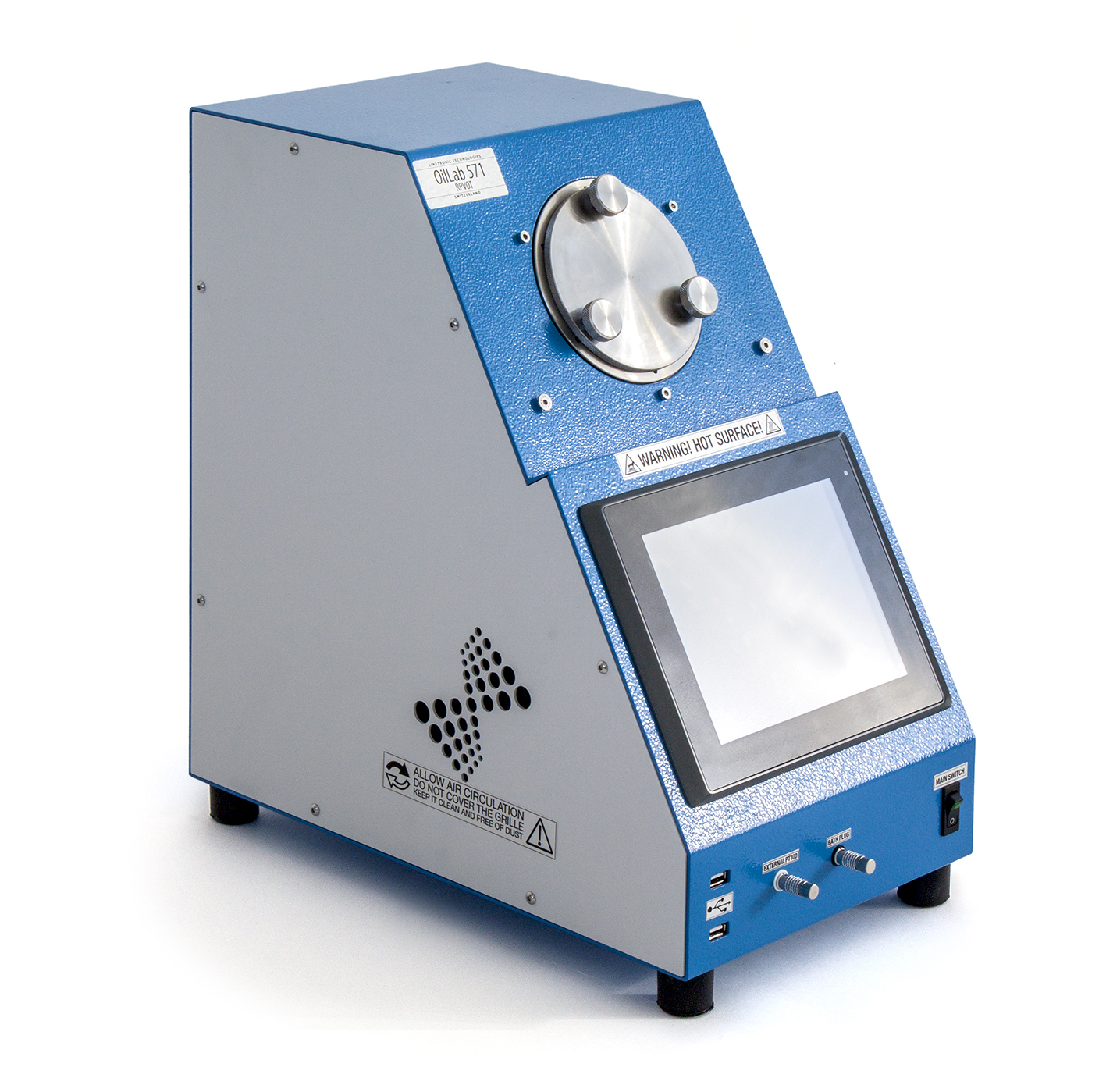

OilLab 571

Oxidation Stability of Steam Turbine Oils

ASTM D942

ASTM D2272

ASTM D4742

ASTM D7098

IP 229

ASTM D942 - Standard Test Method for Oxidation Stability of Lubricating Greases by the Oxygen Pressure Vessel Method.

This test method determines resistance of lubricating greases to oxidation when stored statically in an oxygen atmosphere in a sealed system at an elevated temperature under conditions of test.

ASTM D2272 - Standard Test Method for Oxidation Stability of Steam Turbine Oils by Rotating Pressure Vessel.

This test method utilizes an oxygen-pressured vessel to evaluate the oxidation stability of new and in-service turbine oils having the same composition (base stock and additives) in the presence of water and a copper catalyst coil at 150°C.

ASTM D4742 - Standard Test Method for Oxidation Stability of Gasoline Automotive Engine Oils by Thin-Film Oxygen Uptake (TFOUT).

This test method evaluates the oxidation stability of engine oils for gasoline automotive engines. This test, run at 160 °C, utilizes a high pressure reactor pressurized with oxygen along with a metal catalyst package, a fuel catalyst, and water in a partial simulation of the conditions to which an oil may be subjected in a gasoline combustion engine. This test method can be used for engine oils with viscosity in the range from 4 mm2/s (cSt) to 21 mm2/s (cSt) at 100 °C, including re-refined oils.

ASTM D7098 - Standard Test Method for Oxidation Stability of Lubricants by Thin-Film Oxygen Uptake (TFOUT) Catalyst B.

This test method covers the oxidation stability of lubricants by thin-film oxygen uptake (TFOUT) Catalyst B. This test method evaluates the oxidation stability of petroleum products, and it was originally developed as a screening test to indicate whether a given re-refined base stock could be formulated for use as automotive engine oil (see Test Method D4742). The test is run at 160 °C in a pressure vessel under oxygen pressure, and the sample contains a metal catalyst package, a fuel catalyst, and water to partially simulate oil conditions in an operating engine. In addition, the test method has since been found broadly useful as an oxidation test

of petroleum products.

IP 229 - Relative Oxidation Stability by Rotating Bomb of Mineral Turbine Oil (RBOT).

This method covers a rapid means for estimating the oxidation stability of new turbine oils having the same composition.

OilLab 571

Automatic Oxidation Stability of Steam Turbine Oils ASTM D2272, Dry Bath.

- Compact structure painted with anti-acid epoxy products.

- Heavy designed stainless-steel dry block positioned at 30° equipped with heating elements grant an optimal heat distribution over the entire cell length.

- Magnetic rotation of the internal analysis beaker at 100 rpm.

- Automatic system for charging and de-pressurizing oxygen.

- Linetronic management software running on 8” High-brightness 800cd/m² TFT with resolution 1024 × 768.

- Pre-setting for method ASTM D2272 or customizable analysis parameters.

- Bath temperature controlled by PT100 A Class with 0,1°C precision, automatic for method selected or custom temperature.

- Calibration menu, result browser, dual level password protection.

- More than >60’000 analysis storage capacity.

- 2 × USB for connecting: mouse, keyboard and software updates.

- 1 × RJ45 Ethernet / Lims connection.

- Integrated beeper for end-test notification / errors.

- Dedicated software for real time monitoring and recording.

- Display of the pressure in bar / psi / Kpa.

- Graph creation in real time during the test.

- Invalid test indication in case of pressure leakage.

- Export of files in xls. / .pdf / jpg. format.

- Calibration up to 100 points.

- Rear connection permit to joint to external oxygen line.

- 1 × Glass sample container.

- 1 × Copper catalyst.

- 1 × Beaker cover.

- 1 × Spring clip.

Power Supply

- 230 Vac or 115 Vac

- 50/60 Hz

Temperature Range

- Ambient to +150°C

- With precision 0.1°C

Consumption

Dimensions

Weight

Calibration Accessories

- 3013: Calibration decade box - PT100 Simulator.

- 3102: Kit of connectors and cables.

- 3764: Pressure Calibration Kit.

- Hand pump with connection tube for pressure -0,95 …+ 35,0 bar.

- Adapters.

- Digital pressure gauge -1..+30 Bar rel. +/- 0.1%FS.

- 15902: Stainless steel cover with hole for calibration.

- 3887: Temperature sensor for tank calibration.

3764

Accessories D2272

- 7545: Copper wire catalyst 3 meters, pack of 5 pcs.

- 7146: Silicon carbide paper 100 grit, pack of 100 pcs.

Reference Sample

- 7579: ASTM D2272 reference liquid.

- Approx. 2000 ml.

- Reference value approx. 643 min.

- 7589: ASTM D2272 reference liquid.

- Approx. 2000 ml.

- Reference value approx. 1550 min.

Spare Parts D2272

- 1258: Glass container,175 ml, pack of 3 pcs.

- 7375: Cover in PTFE for glass, pack of 5 pcs.

- 15904: Beaker centering made in PEEK.

- 5620: Spherical cone, pack of 5 pcs.

- 7142: Compensation spring made in stainless steel.

- 7307: O-ring for cell cover, pack of 5 pcs.

- 5681: Holder for glass container.

Optional Accessories

- 1000178: Electric winding mandrel for copper wire catalyst coiling.

- Mounted on solid base with possibility to fix to bench.

- 220 Vac or 115 Vac 50/60 Hz.

- 7590: Linetronic Varclean solution.

- For cleaning the glass cell and interior chamber.

- With spray ended selector.

- 500 ml approx.

- 7151: Copper wire 500 gr, 1.6 mm diameter / approx. 28 m.

- 7153: Copper wire 5000 gr, 1.6 mm diameter / approx. 280 m.

- 942 Kit: Analysis kit to perform the ASTM D942 test.

- Dish holder with 5 glass sample dish.

- Instrument vertical swing-balance system.

- Holder support and centering system.

- Software for ASTM D942 method.

- 4742 Kit: Analysis kit to perform the ASTM D4742/D7098 test.

- Aluminum insert for reduce volume of chamber.

- Glass, Teflon cover and spring.

- Adapter kit for perform method on OilLab 571.

- Software for ASTM D4742 and D7098 method.

1000178

7590

942 Kit

7579 - 7589

Linetronic Technologies SA

Via Onorio Longhi 2 • 6864 Arzo • Mendrisio • Switzerland

tel. +41 91 630 07 03 • fax +41 91 630 07 19

email: info@lin-tech.ch