Laboratory and Process Analyzers

Automatic Analysers → NewLab Range • OilLab Range • Thermofat • OnLine Range

Filterability of Lubricating Oils • Ring and Ball • Foaming Tester • Oxidation Stability • Evaporation Bath • RPVOT (570) • RPVOT (571) • Noack • Air Release • Pensky Martens • Leonardo Pensky Martens • Golleo Abel+Pensky • Aniline Point • Penetration • R.E.C.C. • Abel • Cleveland • Tag • Tag - 6901 • Reid Vapour Pressure • Ductilometer • Herschel Emulsifying • Saybolt Viscometer • Distillation

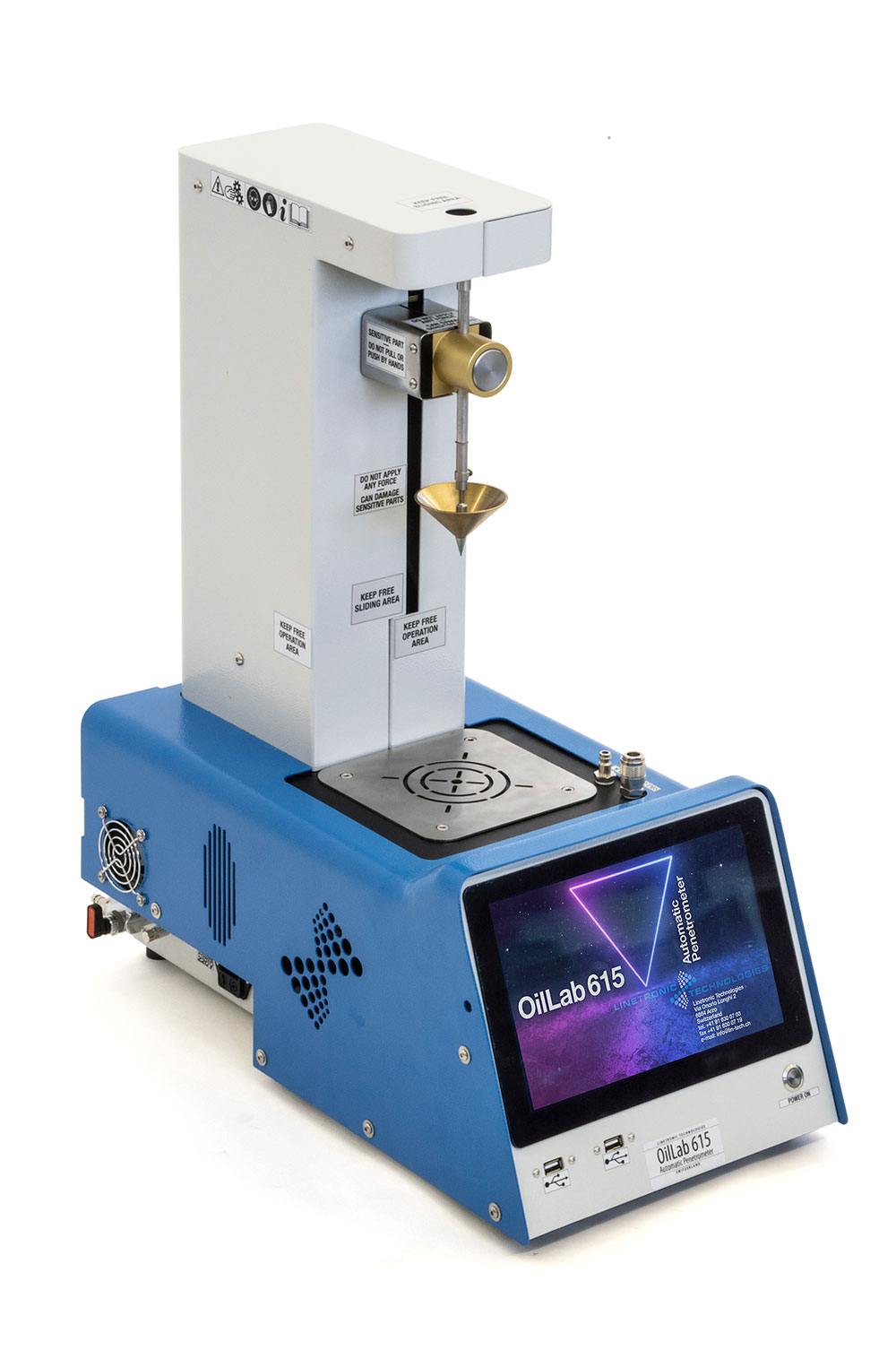

OilLab 615

Penetration

ASTM D5

ASTM D217

ASTM D937

ASTM D1321

ASTM D1403

ASTM D1831

ASTM D2884

DIN 51579

DIN 51580

DIN 51804

DIN 52010

IP 49

IP 50

IP 179

IP 310

IP 376

ISO 2137

NF T60-119

NF T60-132

NF T60-140

Subject

ASTM D5, IP 49, DIN 52010

Penetration of bituminous material.

For determination of the penetration of semi-solid and solid bituminous materials.

ASTM D217, ASTM D1403, IP 50, IP 310, DIN 51804, ISO 2137, NF T60-132, NF T60-140 - Cone penetration of lubricating grease.

Cover four procedures for measuring the consistency of lubricating greases by the penetration of a cone of specified dimensions, mass and finish.

ASTM D937, IP 179, DIN 51580, ISO 2137, NF T60-119 - Cone penetration of petrolatum.

Covers measuring with a penetrometer the penetration of petrolatum as an empirical measure of consistency.

ASTM D1321, IP 376, DIN 51579 - Needle penetration of petroleum waxes.

Covers the empirical estimation of the consistency of waxes derived from petroleum by measurement of the extent of penetration of a standard needle.

This test method is applicable to waxes having a penetration of not greater than 250.

ASTM D1831 - Roll stability of lubricating grease.

Covers determination of the changes in the consistency, as measurably cone penetration, of lubricating greases when worked in the roll stability test apparatus.

ASTM D2884 - Yield stress of heterogeneous propellants by cone penetration method.

Covers determination of the yield stress of heterogeneous propellants, both of the gel and emulsion types, containing from 0 to 70% solid additives.

Main Features

- Bench top instrument compact and solid structure bi-color painted, and last generation dedicated electronic boards.

- Analytical head made in aluminium and corrosion resistant plastics, advanced automatic up-down movement and sample surface positioning system, pen. range up to 60 mm.

- Transfer dish for water conditioning sample with quick-joints able to achieve temperature from -10°C room temperature and up to +46.1°C.

- Safety systems: head malfunctioning movement.

- Linetronic Management software running on 10.1” High-brightness 800cd/m² TFT with resolution 1280 × 700:

- pre-setting for method ASTM, DIN, IP and ISO, or customizable analysis parameters;

- advanced surface detection with adjustable sensitivity;

- settable bath temperature and controlled by PT100 A Class with 0,1°C precision, automatic for method selected or custom temperature;

- calibration menu, result browser, dual level password protection;

- more than 60’000 analysis storage capacity;

- 2 × USB for connecting: mouse, keyboard and software updates;

- 1 × RJ45 Ethernet / Lims connection;

- integrated beeper for end-test notification / errors;

- export file in .xls format.

- Plunger 47.5 g.

- ASTM D217 optional cone.

- Sample levelling spatulas.

Dimensions

- width 28 cm

- depth 54 cm

- height 73 cm

Weight

Power Supply

General Accessoires

- 6033: 50 g plunger weight.

- 6034: 100 g plunger weight.

- 3421-15135: USB led light and positioning mirror for semi-automatic option (for OilLab 615).

Spare Parts

- 5783+16772: plunger 47.5 g (for OilLab 615 only).

Accessoires ASTM D217, IP 50

- 5306: optional penetration cone ASTM D217, 65 mm diameter, brass body and stainless-steel tip.

- 5308: standard penetration cone ASTM D217, 69 mm diameter, aluminium body and stainless-steel tip.

- 5310: optional penetration cone ASTM D217, 65 mm diameter, body and tip of stainless steel, for European Pharmacopoeia.

- 5312: sample container 76.5 × 63.5 mm, made in brass, pack of 3 pcs.

- 5313: external ring for grease restraint/recovery, 203 mm diameter.

Accessoires ASTM D5, IP 49, EN 1426

- 5053: penetration needle ASTM D 5, IP 49, 2.5 g, pack of 3 pcs.

- 5480: long penetration needle ASTM D 5, IP 49, 2.5 g, pack of 3 pcs.

- 5481: reduction ring for reduce sample volume, external diameter 53 mm, internal diameter 36 mm, 20 mm height, for EN 1426 method.

- 5482: reduction ring for reduce sample volume, external diameter 53 mm, internal diameter 36 mm, 30 mm height, for EN 1426 method.

- 5483: sample container 55 × 35 mm, made in brass, pack of 5 pcs.

- 5407: sample container 55 × 45 mm, made in brass, pack of 5 pcs.

- 5484: sample container 70 × 45 mm, for bitumen, penetrations between 200 and 350, made in brass, pack of 5 pcs.

- 5409: sample container 70 × 60 mm, for bitumen, penetrations between 350 and 500, made in brass, pack of 5 pcs.

Accessoires ASTM D1403

- 5485: penetration cone ½ ASTM D1403 IP 310, 22.5 g, body and tip in stainless steel.

- 5486: slider ½, 15 g.

- 5403: sample container ½, 38 × 32 mm, pack of 3 pcs.

- 5488: penetration cone ¼, ASTM D1403, IP 310, 1.20 gr, body Plexiglas®, stainless steel tip.

- 5571: slider ¼ 8.18 gr.

- 5490: sample container ¼, 19 × 11.5 mm, pack of 3 pcs.

Accessoires ASTM D937

- 5306: optional penetration cone ASTM D217, 65 mm diameter, body of brass, stainless steel tip.

- 5479: sample container 100 × 65 mm, made in steel with cover, pack of 3 pcs.

Accessoires ASTM D1321, DIN 51579, IP 376

- 5591: needle ASTM D1321, 2.5 gr, stainless steel.

- 16095: sample container wax test cylinder 25 × 32 mm, pack of 2 pcs.

- 5592: base plate in brass 63.5 × 38, pack of 2 pcs.

Linetronic Technologies SA

Via Onorio Longhi 2 • 6864 Arzo • Mendrisio • Switzerland

tel. +41 91 630 07 03 • fax +41 91 630 07 19

email: info@lin-tech.ch