Laboratory and Process Analyzers

Automatic Analysers → NewLab Range • OilLab Range • Thermofat • OnLine Range

Filterability of Lubricating Oils • Ring and Ball • Foaming Tester • Oxidation Stability • Evaporation Bath • RPVOT (570) • RPVOT (571) • Noack • Air Release • Pensky Martens • Leonardo Pensky Martens • Golleo Abel+Pensky • Aniline Point • Penetration • R.E.C.C. • Abel • Cleveland • Tag • Tag - 6901 • Reid Vapour Pressure • Ductilometer • Herschel Emulsifying • Saybolt Viscometer • Distillation

OilLab 570

Oxidation Stability by Pressure Vessel

ASTM D2112 - ASTM D2272 - ASTM D4742 - ASTM D7098

IP 229

Subject

Gum Content in Fuels by Jet Evaporation

This test method covers the determination of the existent gum content of aviation fuels, and the gum content of motor gasolines or other volatile distillates in their finished form (including those containing alcohol and ether type oxygenates and deposit control additives) at the time of test.

ASTM D2112 - Oxidation Stability of Inhibited Mineral Insulating Oil by Pressure Vessel

This test method is intended as a rapid method for the evaluation of the oxidation stability of new mineral insulating oils containing a synthetic oxidation inhibitor. This test is considered of value in checking the oxidation stability of new mineral insulating oils containing 2,6-ditertiary-butyl para-cresol or 2,6-ditertiary-butyl phenol, or both, in order to control the continuity of this property from shipment to shipment. The applicability of this procedure for use with inhibited insulating oils of more than 12 cSt at 40°C (approximately 65 SUS at 100°F) has not been established.

ASTM D2272 - Oxidation Stability of Steam Turbine Oils by Rotating Pressure Vessel (RBOT)

This test method utilizes an oxygen-pressured vessel to evaluate the oxidation stability of new and in-service Turbine oils having the same composition (base stock and additives) in the presence of water and a copper catalyst coil at 150°C.

ASTM D4742 - Oxidation Stability of Gasoline Automotive Engine Oils by Thin-film Oxygen Uptake (TFOUT)

This test method evaluates the oxidation stability of engine oils for gasoline automotive engines. This test, run at 160°C, utilizes a high pressure reactor pressurized with oxygen along with a metal catalyst package, a fuel catalyst, and water in a partial simulation of the conditions to which an oil may be subjected in a gasoline combustion engine. This test method can be used for engine oils with viscosity in the range from 4 mm2/s (cSt) to 21 mm2/s (cSt) at 100°C, including re-refined oils.

ASTM D7098 - Standard Test Method for Oxidation Stability of Lubricants by Thin-Film Oxygen Uptake (TFOUT) Catalyst B

This test method covers the oxidation stability of lubricants by thin-film oxygen uptake (TFOUT) Catalyst B. This test method evaluates the oxidation stability of petroleum products, and it was originally developed as a screening test to indicate whether a given re-refined base stock could be formulated for use as automotive engine oil (see Test Method D4742). The test is run at 160 °C in a pressure vessel under oxygen pressure, and the sample contains a metal catalyst package, a fuel catalyst, and water to partially simulate oil conditions in an operating engine. In addition, the test method has since been found broadly useful as an oxidation test of petroleum products.

IP 229 - Relative Oxidation Stability by Rotating Bomb of Mineral Turbine Oil (RBOT)

This method covers a rapid means for estimating the oxidation stability of new turbine oils having the same composition.

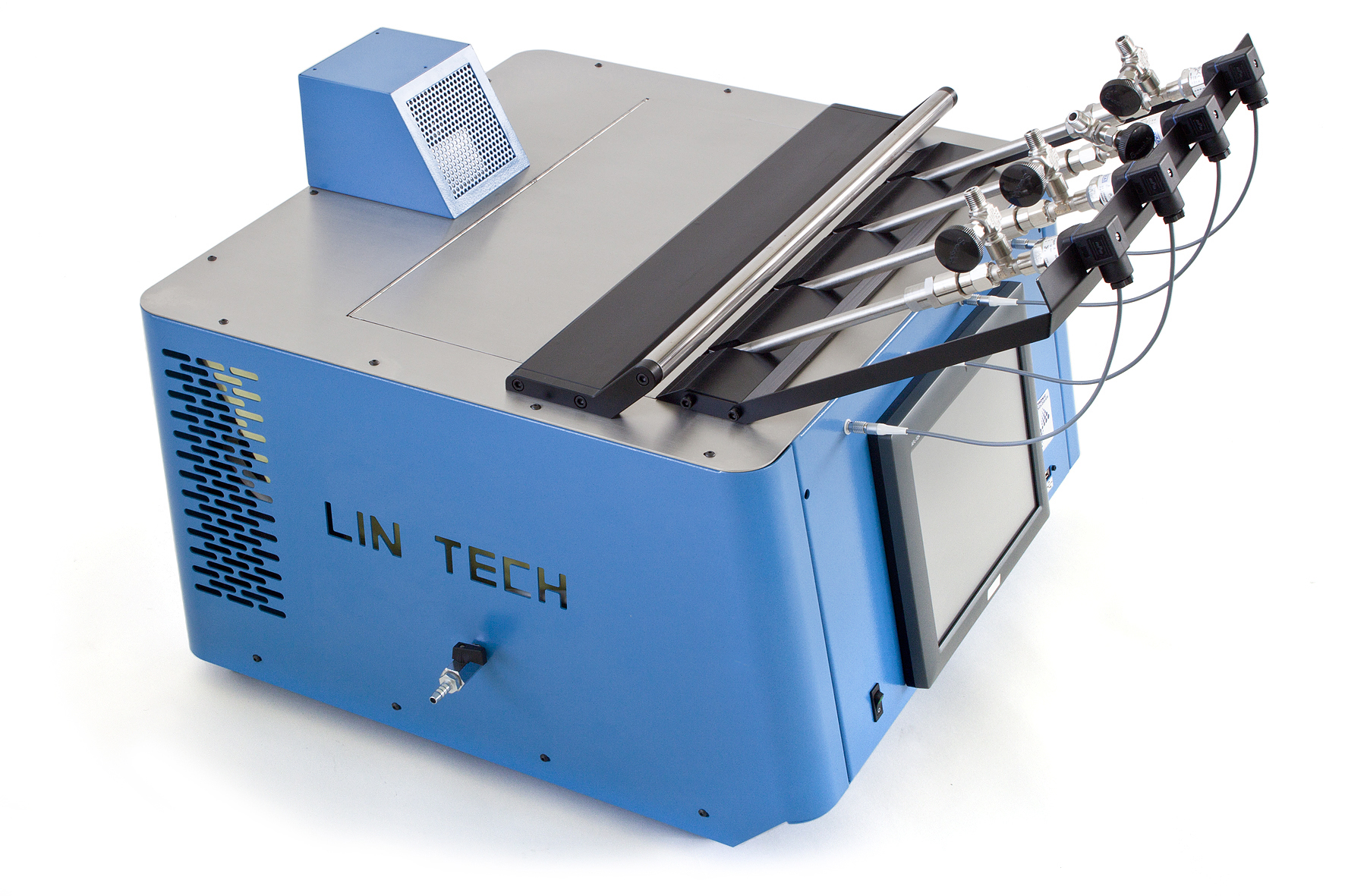

OilLab 570-SA

Automated Oxidation Stability Bath by Pressure Vessel (RPVOT), 4 places

- Compact structure painted with anti-acid epoxy products.

- Heavy designed stainless-steel bath with capacity of approx. 40 liters and equipped with lateral drain valve for easily empty the bath.

- Double total immersion heating elements allow perfect bath stability and temperature range from ambient up to +199°C, stability +/- 0.1°C.

- Uniformity is granted by internal motorized stirring system and protection/diffusion grid.

- Upper part made in stainless-steel for easily cleaning equipped with heating resistant handle for open/close the bath port.

- 4 position support equipped with bearings grants 30° angle vessel-rotation.

- 4 Rear independents motors grant vessel rotation of 100 rpm according to the ASTM specifications, individually speed setting for easily calibration.

- Bath equipped with a Touch Screen panel PC:

- TFT/LCD 12”

- 40 Gb HD

- Resolution 1024 × 768 and 16M colours

- 2 × USB Ports

- The dedicated software manages:

- The motors for the rotation of the 4 cylinders independently;

- The bath temperatures by means of a PT100 sensor class A that can be displayed in °C / °F, including the overtemperature safety alarm.

- Dedicated software for real time monitoring and recording that includes:

- 5 methods (12 / 24 / 48 / 96 and 192 hours)

- Display of the pressure in bar / psi / Kpa

- Graph creation

- Export of files in xls. and / or jpg. format

- Calibration

Power Supply

- 230 Vac or 115 Vac, 50/60 Hz

Temperature Range

- Ambient to +199°C

- Precision 0.1°C

Consumption

Dimensions

Weight

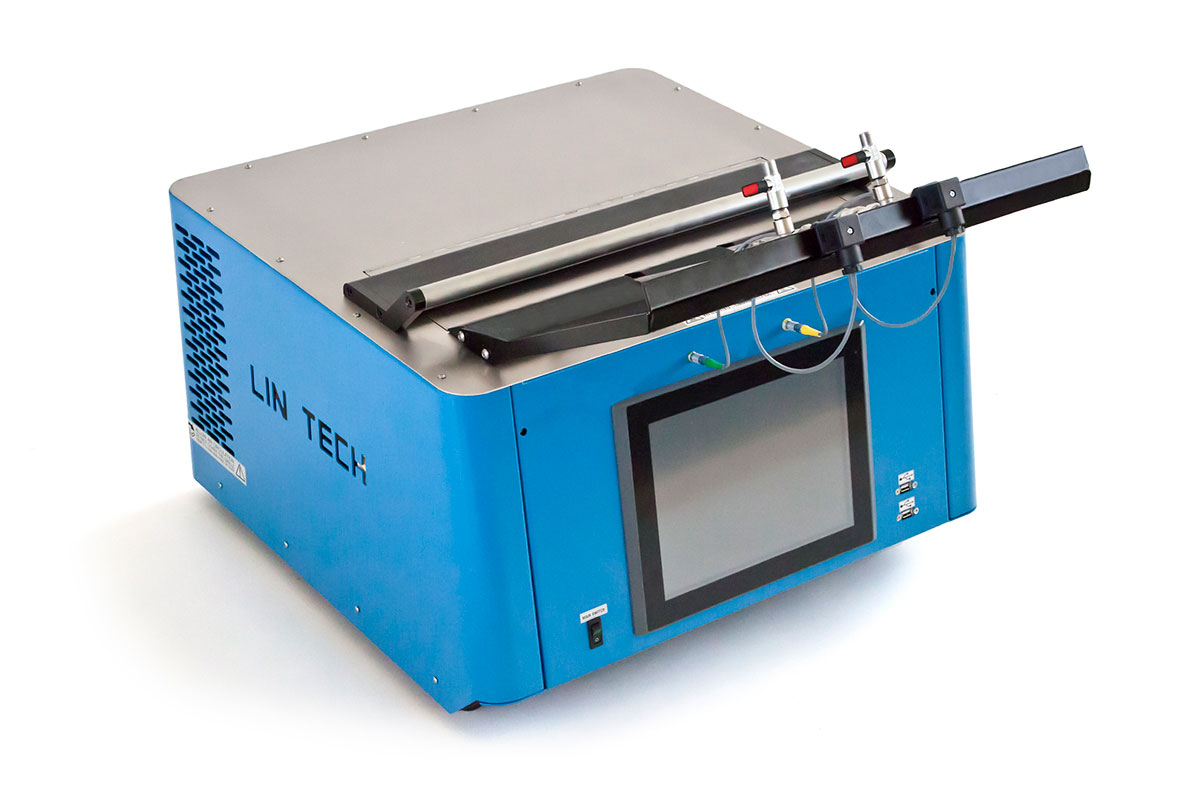

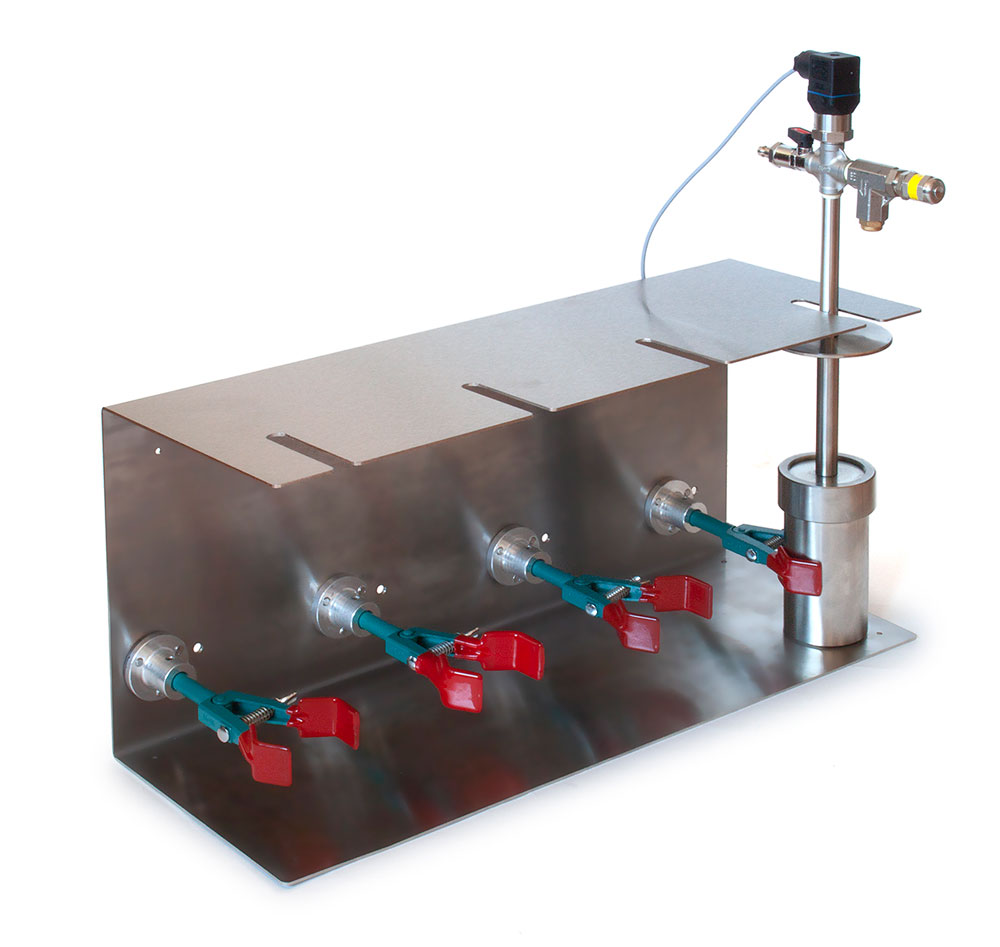

OilLab 570-2-SA

Automated Oxidation Stability Bath by Pressure Vessel (RPVOT), 2 places

- Compact structure painted with anti-acid epoxy products.

- Heavy designed stainless-steel bath with capacity of approx. 40 Liters and equipped with lateral drain valve for easily empty the bath.

- Double total immersion heating elements allow perfect bath stability and temperature range from ambient up to +199°C, stability +/- 0.1°C.

- Uniformity is granted by internal motorized stirring system and protection/diffusion grid.

- Upper part made in stainless-steel for easily cleaning equipped with heating resistant handle for open/close the bath port.

- 2 position support equipped with bearings grants 30° angle vessel-rotation.

- 2 rear independents motors grant vessel rotation of 100 rpm according to the ASTM specifications, individually speed setting for easily calibration.

- Bath equipped with a Touch Screen panel PC:

- TFT/LCD 12”

- 40 Gb HD

- Resolution 1024 × 768 and 16M colours

- 2 × USB Ports

- The dedicated software manages:

- The motors for the rotation of the 2 cylinders independently;

- The bath temperatures by means of a PT100 sensor class A that can be displayed in °C / °F, including the overtemperature safety alarm.

- Dedicated software for real time monitoring and recording that includes:

- 5 methods (12 / 24 / 48 / 96 and 192 hours)

- Display of the pressure in bar / psi / Kpa

- Graph creation

- Export of files in xls. and / or jpg. format

- Calibration

Power Supply

- 230 Vac or 115 Vac, 50/60 Hz

Temperature Range

- Ambient to +199°C

- Precision 0.1°C

Consumption

Dimensions

Weight

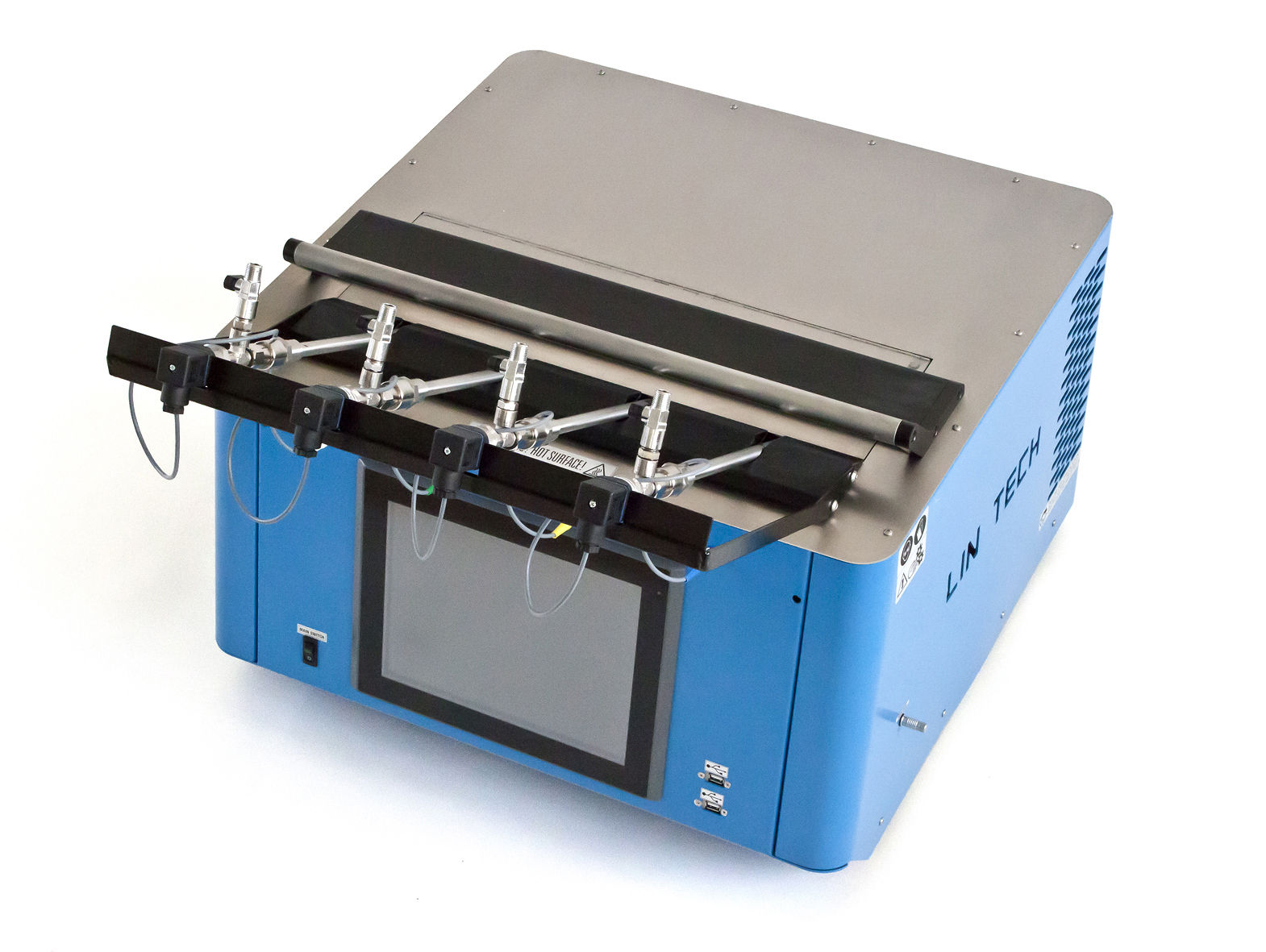

OilLab 570-D

Automated Oxidation Stability Dry Bath by Pressure Vessel (RPVOT), 4 places

- Compact structure painted with anti-acid epoxy products.

- Heavy designed stainless-steel dry block positioned at 30° equipped with heating elements grant an optimal heat distribution over the entire cell length from ambient up to +199°C, stability +/- 0.1°C.

- Upper part made in stainless-steel for easily cleaning equipped with heating resistant handle for open/close the bath port.

- 4 position support equipped with bearings grants 30° angle vessel-rotation.

- 4 rear independents motors grant vessel rotation of 100 rpm according to the ASTM specifications, individually speed setting for easily calibration.

- Bath equipped with a Touch Screen panel PC:

- TFT/LCD 12”

- 40 Gb HD

- Resolution 1024 × 768 and 16M colours

- 2 × USB Ports

- The dedicated software manages:

- The motors for the rotation of the 4 cylinders independently;

- The bath temperatures by means of a PT100 sensor class A that can be displayed in °C / °F, including the overtemperature safety alarm.

- Dedicated software for real time monitoring and recording that includes:

- 5 methods (12 / 24 / 48 / 96 and 192 hours)

- Display of the pressure in bar / psi / Kpa

- Graph creation

- Export of files in xls. and / or jpg. format

- Calibration

Power Supply

- 230 Vac or 115 Vac, 50/60 Hz

Temperature Range

- Ambient to +199°C

- Precision 0.1°C

Consumption

Dimensions

Weight

Accessories for Liquid Bath

- 7223: Silicon Oil

- Viscosity approx. 350 mm² / S @ 25 °C

- Suitable for working temperatures up to +220 °C

- Can of 20 litres

- Requested quantity 2 cans

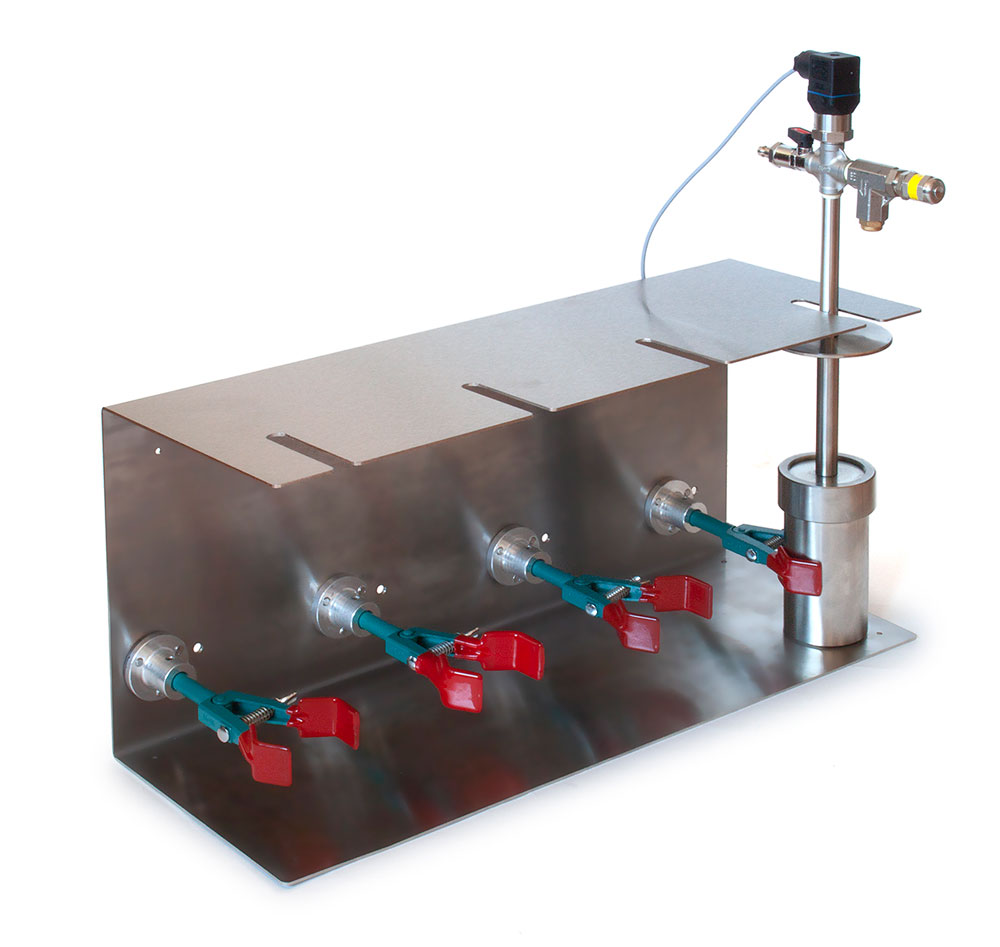

Common Accessories

- 5949: Automatic Pressure Vessel RPOVT.

- According to ASTM D2112, D2272, D4742, D7098.

- Made in high quality corrosion resistant stainless-steel.

- O-ring for stem.

- O-ring for lid.

- Stainless-steel stem calibrated.

- Needle valve on top for pressurizing/de-pressurizing.

- ¼” Female connection pressure reader.

- Pressure sensor 0-16 bar rel.

Accessories D2112

- 1258: Glass sample container 175 ml.

- 7140: PTFE cover, pack of 10 pcs.

- 7142: Retaining hold-down spring made in stainless steel.

- 7545: Copper wire catalyst 3 meters, pack of 5 pcs.

- 7146: Silicon carbide paper 100 grit, pack of 100 pcs.

- T-AS96C: Thermometer ASTM 96C.

Accessories D2272

- 1258: Glass sample container 175 ml.

- 7668: PTFE cover with 4 holes, pack of 10 pcs.

- 7142: Retaining hold-down spring made in stainless steel.

- 7545: Copper wire catalyst 3 meters, pack of 5 pcs.

- 7146: Silicon carbide paper 100 grit, pack of 100 pcs.

- T-IP37C: Thermometer IP 37C.

Accessories D4742 – D7098

- 1260: Glass container.

- 7669: PTFE cover with 1 hole, pack of 10 pcs.

- 7142: Retaining hold-down spring made in stainless steel.

- 7149: Aluminum insert made of 2024.

- T-AS102C: Thermometer ASTM 102C IP 83C.

Optional Accessories

- 1000178: Electric winding mandrel for copper wire catalyst coiling:

- Mounted on solid base with possibility to fix to bench;

- 220 Vac or 115 Vac 50/60 Hz.

- 7590: Linetronic Varclean solution:

- For cleaning the RBOT glass cell and internal chamber;

- With spray ended selector;

- 500 ml approx.

- 7151: Copper wire 500 gr, 1.6 mm diameter / approx. 28 m.

- 7153: Copper wire 5000 gr, 1.6 mm diameter / approx. 280 m.

- 5853: Rack for vessel:

- During the assembly and disassembly;

- 4 positions;

- Including key for easy demounting.

- LAB-O2-transfer kit: Oxygen transfer kit with quick coupling Extensible polyurethane tube 1.6 meters minimum length

Accessories for Performance Verification

- 7579: RBOT D2272 reference liquid:

- Approx. 2000 ml;

- Reference value approx. 643 min.

- 7589: RBOT D2272 reference liquid:

- Approx. 2000 ml;

- Reference value approx. 1550 min.

1000178

7590

5853

7579 - 7589

Linetronic Technologies SA

Via Onorio Longhi 2 • 6864 Arzo • Mendrisio • Switzerland

tel. +41 91 630 07 03 • fax +41 91 630 07 19

email: info@lin-tech.ch