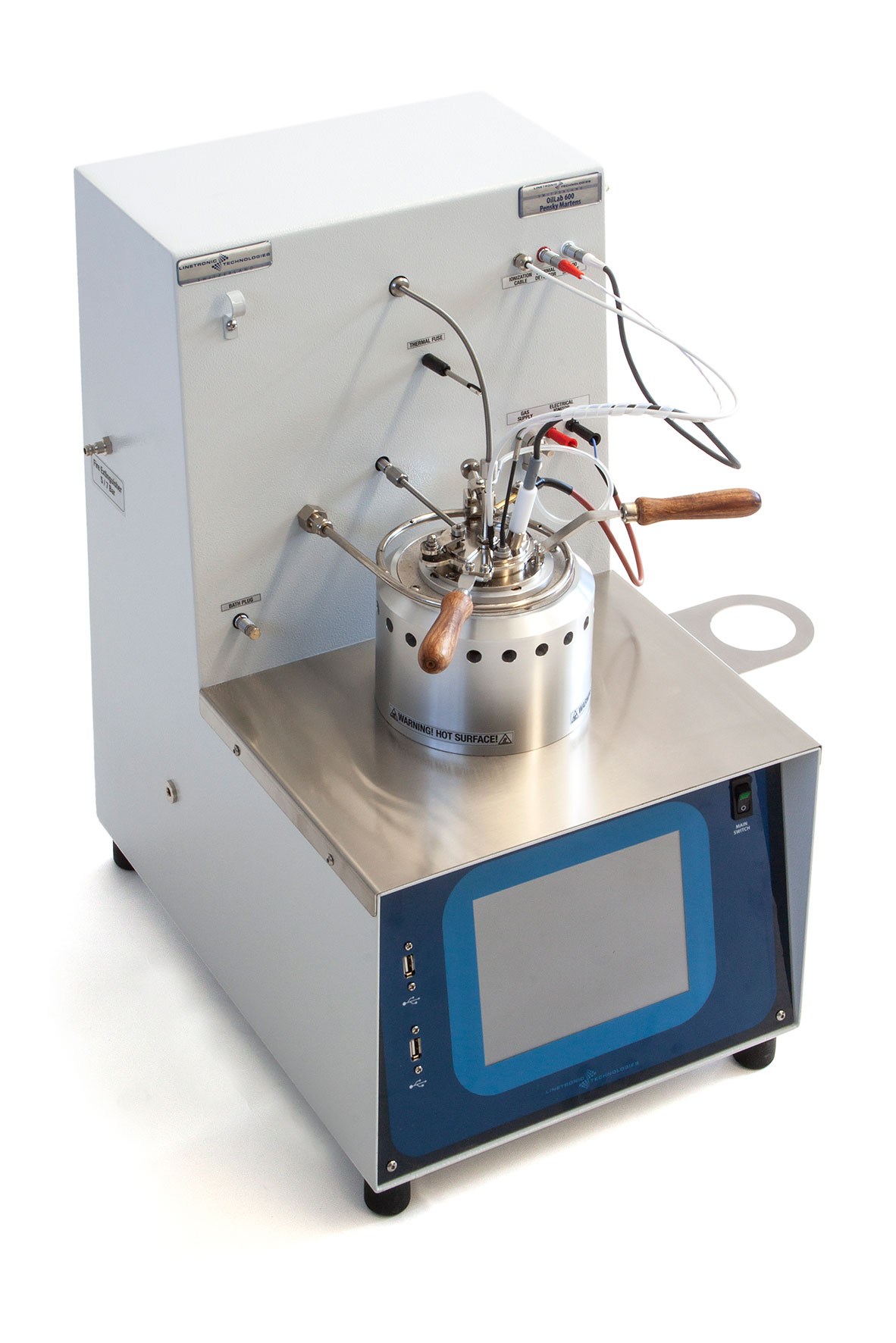

Laboratory and Process Analyzers

Automatic Analysers → NewLab Range • OilLab Range • Thermofat • OnLine Range

Filterability of Lubricating Oils • Ring and Ball • Foaming Tester • Oxidation Stability • Evaporation Bath • RPVOT (570) • RPVOT (571) • Noack • Air Release • Pensky Martens • Leonardo Pensky Martens • Golleo Abel+Pensky • Aniline Point • Penetration • R.E.C.C. • Abel • Cleveland • Tag • Tag - 6901 • Reid Vapour Pressure • Ductilometer • Herschel Emulsifying • Saybolt Viscometer • Distillation

Flash Point on petroleum products, gas oils, fuel oils, lubrificants, biodiesel. Suitable for flash point detection on different substances, waste materials, solvents…

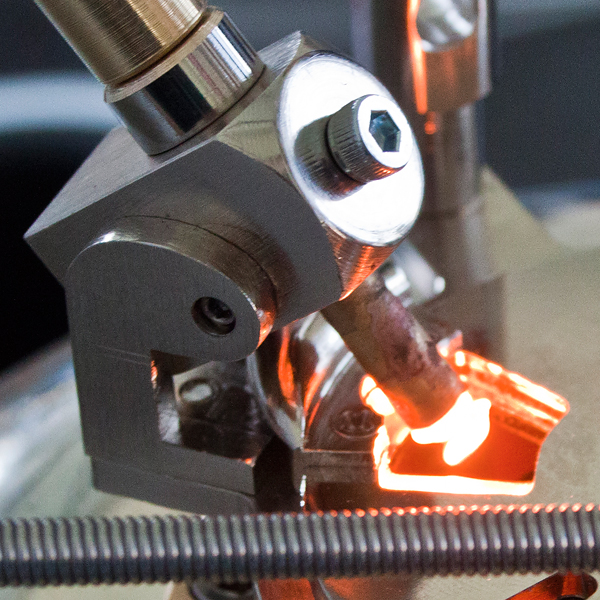

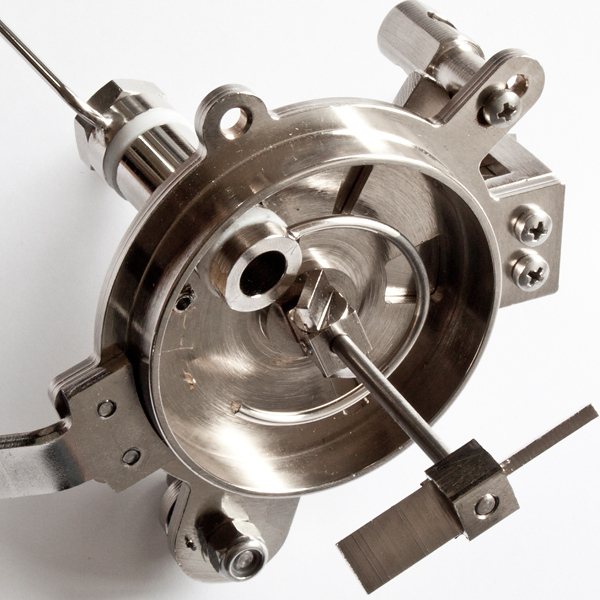

The sample is heated and stirred at specified rates, using one of three defined procedures (A, B, or C). An ignition source is directed into the test cup at regular intervals with simultaneous interruption of the stirring, until a flash is detected.

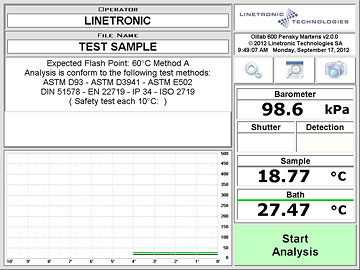

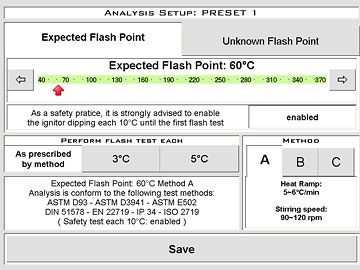

Easy, user-friendly graphics display the essential analysis parameters in real time during testing.

A graphical format allows the operator a quick view of the desired parameters displayed on the monitor of the integrated touch screen panel PC.

A simple click to start a new analysis.

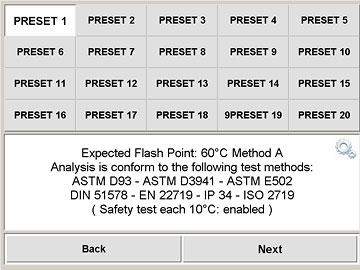

In order to aid the operator and reduce set-up time, it is possible to introduce the characteristics of a sample such as: name of the file, expected flash point and procedure / test method to be carried out by storing the data in one of the 20 available presets.

Thanks to this pre-programming, products that are commonly tested may have their own procedure or profile.

By selecting the relevant preset, set up time of analysis preparation is greatly reduced.

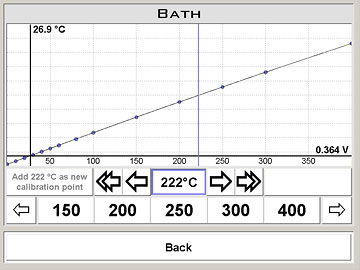

Two calibration modes assure an improved precision.

The standard calibration is based on 5 predefined points while the dynamic calibration can be performed on up to 100 points allowing to set the points within the range of greater interest.

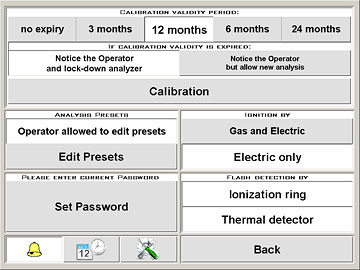

Calibration validity can also be set.

This ensures greater compliance with internal procedures in adherence to the quality system of each laboratory.

The calibration can be scheduled every 3, 6, 12 and 24 months or not have an expiry date.

It is also possible to by-pass the expiration date alert from the system and allow the user to continue the analysis or "lock-out" the operator from continuing the analysis.

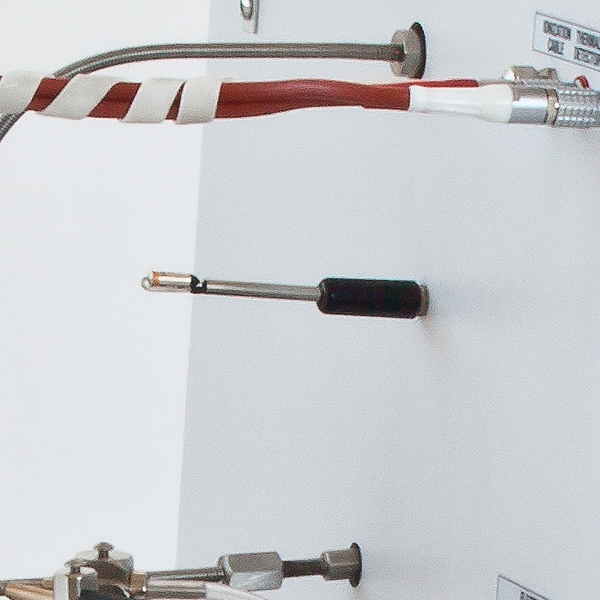

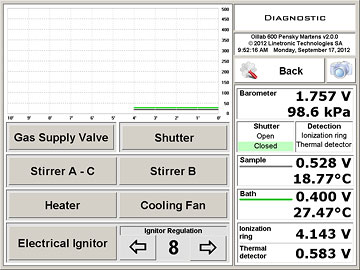

By means of the diagnostic menu it is possible to perform an accurate check of the instrument and its essential components.

Stirrer, gas valve, shutter, cooling fan, heater and electrical ignitor can be monitored by pressing the corresponding key.

Diagnostic monitoring of the sample and bath temperature sensors will be in Volts and in °C while the Ionization ring and thermal detector will be in Volts. The values of the barometric sensor will be in Volts and kPa.

All of these data that can be valuable information in the trouble-shooting in case of failure.

To each product its analysis.

It has never been so easy to perform the set-up of the analysis.

The operator will choose between a procedure for an unknown sample and a sample with an expected flash point. Set temperature of the latter by sliding finger on the temperature bar of the touch screen panel PC.

Select method to be performed between A, B and C with its heating ramp and stirrer speed.

Set interval of degrees for the introduction of the flame and / or ignitor to the sample cup.

Select, if desired, to save all parameters in one of the 20 available presets.

The password protection allows the storing and securing of the setting parameters.

By activating the password protection, access to the configuration parameter is limited and only permitted to the administrator.

Linetronic Technologies SA

Via Onorio Longhi 2 • 6864 Arzo • Mendrisio • Switzerland

tel. +41 91 630 07 03 • fax +41 91 630 07 19

email: info@lin-tech.ch